Integration. Scalability. Versatility.

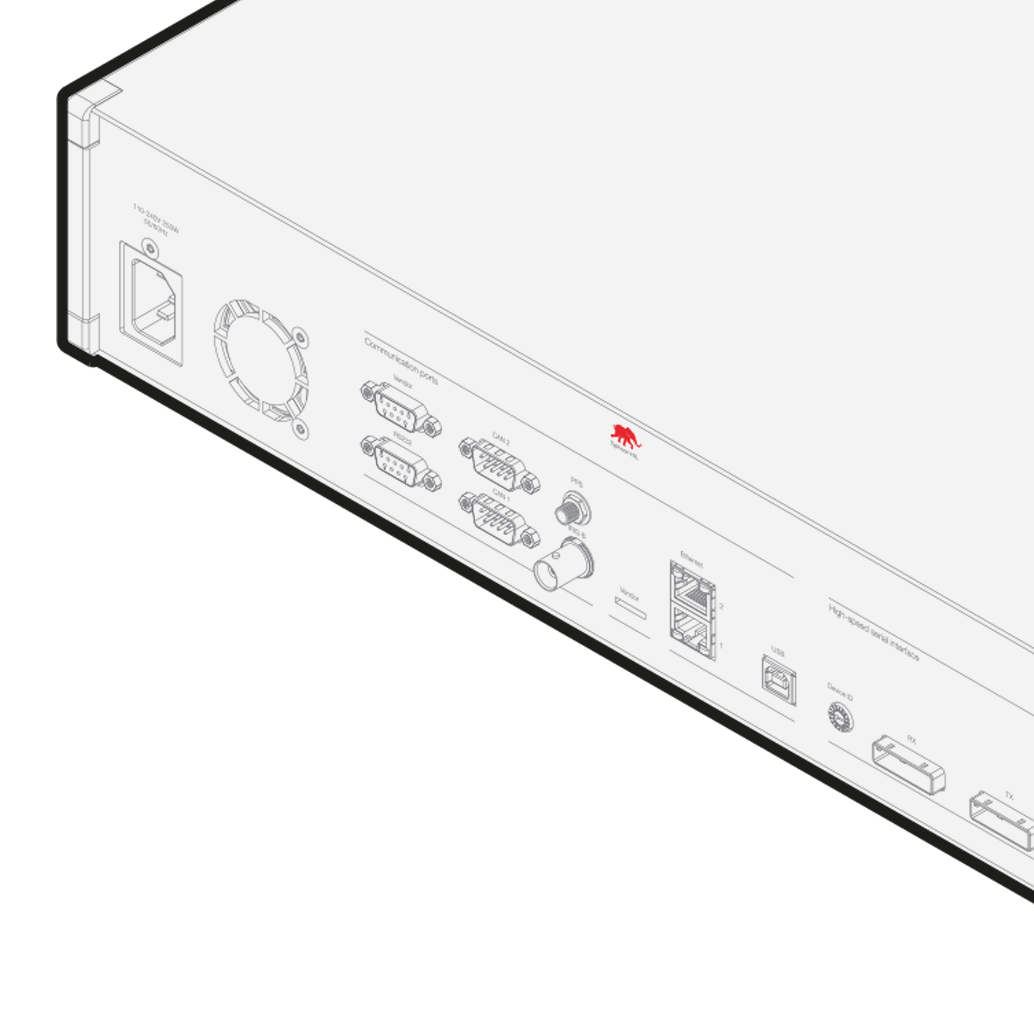

HIL604

Our HIL604 real-time simulator sets the industry standard for controls testing, validation, pre-certification, and optimization for power electronics systems, motor drives, and grid modernization applications.

The HIL604 is the ideal fit if you are looking for a seamless scalability, which can support up to 16 HIL units operating as one unified HIL system. Multi-unit HIL604 testbeds can simulate large systems with more than a hundred power electronics converters, displaying its unrivaled performance thus empowering you to stay ahead of your competition.

Whether you are testing a single power electronics converter control or multiple converter system, the HIL604 provides an integrated environment that is as easy-to-use. Compiling a model, interacting with real-time simulation in runtime, automating tests, and is convenient for even first-time HIL users.

Our HIL604 device provides you with the ability to:

- Unleash the 8-core processor HIL for real-time emulation of up to 8 converters.

- Emulate your power stage with down to 50ns simulation time step (typically 500ns).

- Interface your controller via 64 analog outputs, 32 analog inputs, 64 digital inputs, and 64 digital outputs.

- Sample digital inputs with 7 ns sampling resolution

- Quickly find problems and debug your controller with new Scope/Capture Function

- Dive into your signals with 1 Megapoint capture record length for all 64 channels.

- Build converter models using our extensive library of power electronics components and prepackaged examples.

- Automate testing with Python scripts for the most comprehensive control software testing.

- Connect to the host PC via Ethernet or USB2.0.

| HIL604 Technical details | |

|---|---|

| Processor | Up to 6 core |

| Channels | 64 x Analog outputs (AO); 64 x Digital outputs (DO); 64 x Digital inputs (DI); 32 x Analog inputs (AI) |

| Resolution | 16 bit ADC |

| Connectivity | Analog I/O (1 x DIN 41612, type C, 96 pin male connector); Digital I/O (1 x DIN 41612, type C, 96 pin male connector); USB 2.0 (1 x B-type connector); Ethernet (2 x 10/100/1000 Mbps RJ45 connector); CAN (2 x DB9 plug); RS232 (1 x DB9 receptacle); High speed serial link (2 x PCIe 4x connector, 8 lane, 5 GHz) |

| Housing | 2U 19” rack-mountable unit, up to 10 kg |

| Software | Typhoon HIL Control Center (THCC) |