e-Drive

ECU Testing for Electric Drive Units. Reimagined.

In the rapidly evolving landscape of electric vehicles (EVs), ensuring the reliability of electronic control units (ECUs) is paramount to driver safety and system performance. Manufacturers face increasing pressures to accelerate development, testing, and validation of high-performance electric drive (e-Drive) units against shrinking timelines, limited engineering resources, and reduced budgets. Robust and continuous testing, leveraging specialized testing benches, real-time simulation, and advanced modeling tools, offers a future-proof solution to these challenges. Typhoon HIL’s Hardware-in-the-Loop (HIL) solutions are tailored to address these industry challenges, providing a comprehensive approach to ECU testing that ensures system reliability and performance.

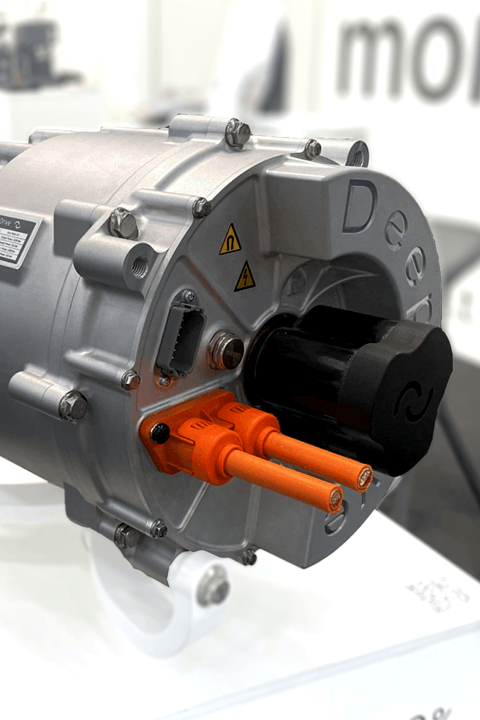

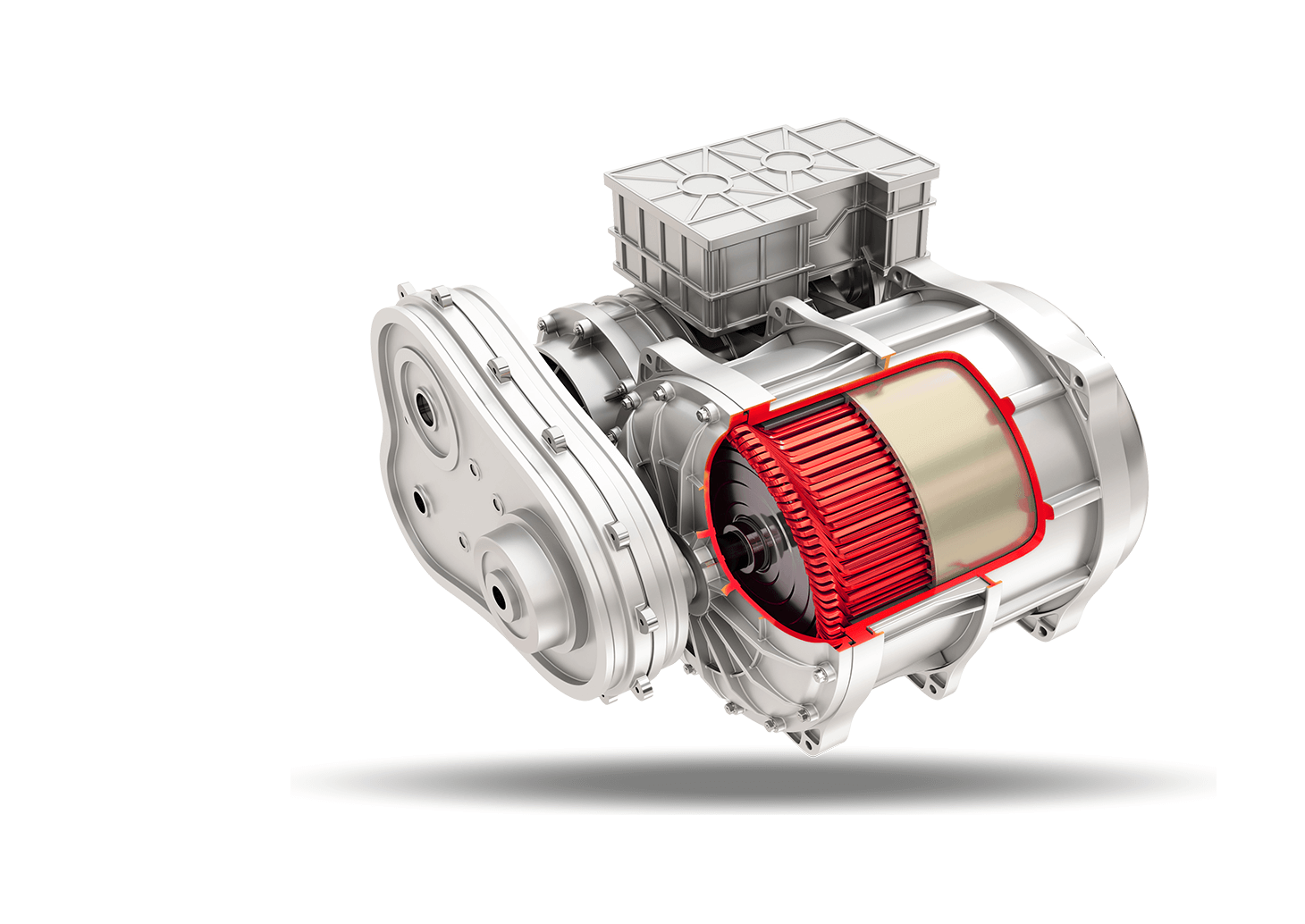

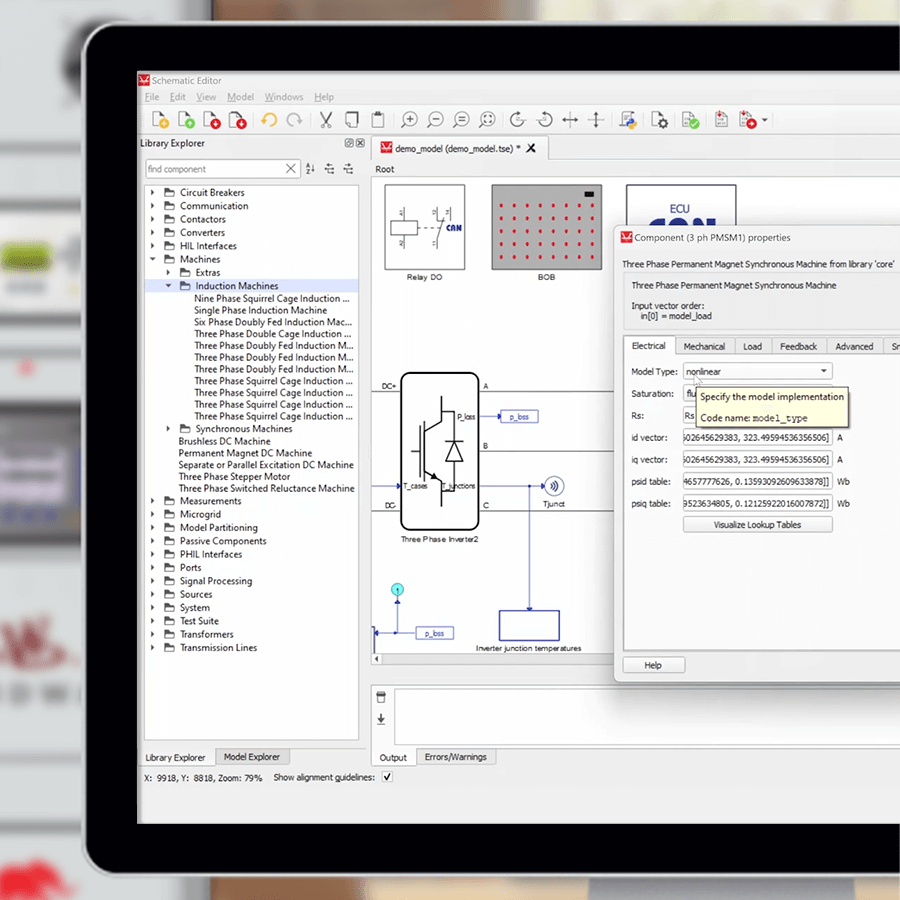

Detailed Machine and

Inverter Models

Typhoon HIL’s solutions feature an extensive library of electric machines and detailed inverter models, including switching device loss modeling and spatial-harmonic electric machine models. These high-fidelity models enable precise simulation of real-world conditions, facilitating accurate testing and validation of motor drives for EVs. The platform’s user-friendly interface and comprehensive documentation ensure that engineers can efficiently design, test, and validate their systems, streamlining the development process and enhancing overall productivity.

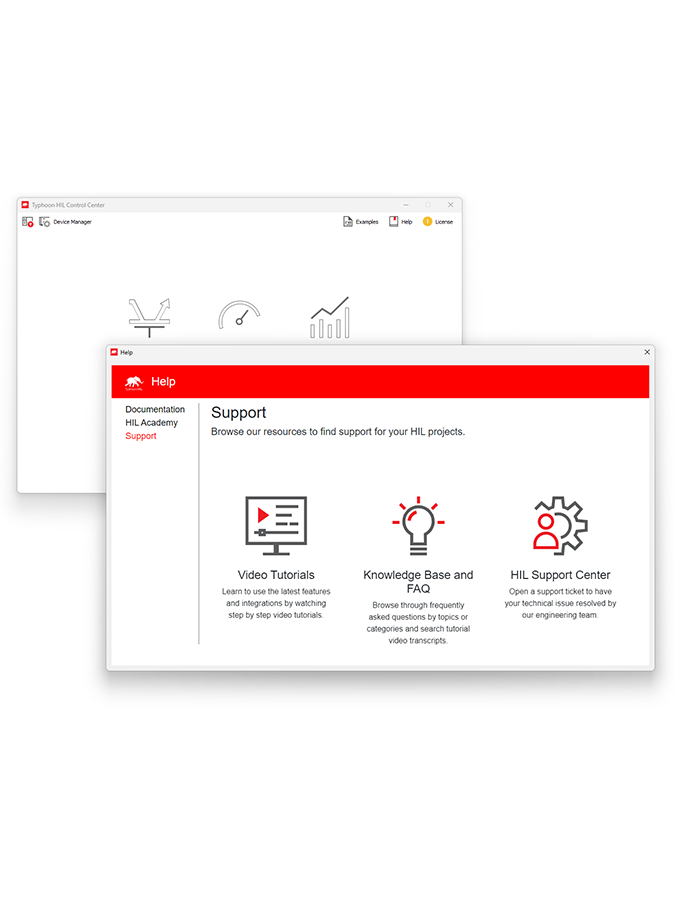

Ease of Use and Comprehensive Support

Designed with user experience in mind, Typhoon HIL’s platform offers intuitive tools and resources that simplify the testing process. The system’s plug-and-play interface ensures seamless integration with third-party test automation tools via XIL ASAM compatible API, reducing setup time and minimizing potential integration issues. Comprehensive support materials, including detailed documentation, application notes, and a vibrant user community, provide invaluable assistance to engineers at every stage of development. This commitment to ease of use and support empowers teams to focus on innovation and efficiency, driving the advancement of e-Mobility solutions.