e-Mobility

Drive Your e-Mobility Efforts Forward

Typhoon HIL is more than a testing solution—we’re your trusted partner in e-Mobility innovation. With deep expertise in real-time simulation and HIL testing, our vertically integrated platform and high-fidelity models drive the development and validation of EV powertrains, e-Drive systems, BMS, fuel cells, OBCs, EVSE, and DC/DC converters. Ensuring seamless interoperability across powertrain components, charging systems, and vehicle-to-grid technologies, we enable you to validate complex systems with precision and efficiency—long before hardware deployment.

Recognized for our rapid global delivery, dedicated engineering support, and hyper-personalized commissioning team, we provide the reliability and speed you need to bring your innovations to market with confidence.

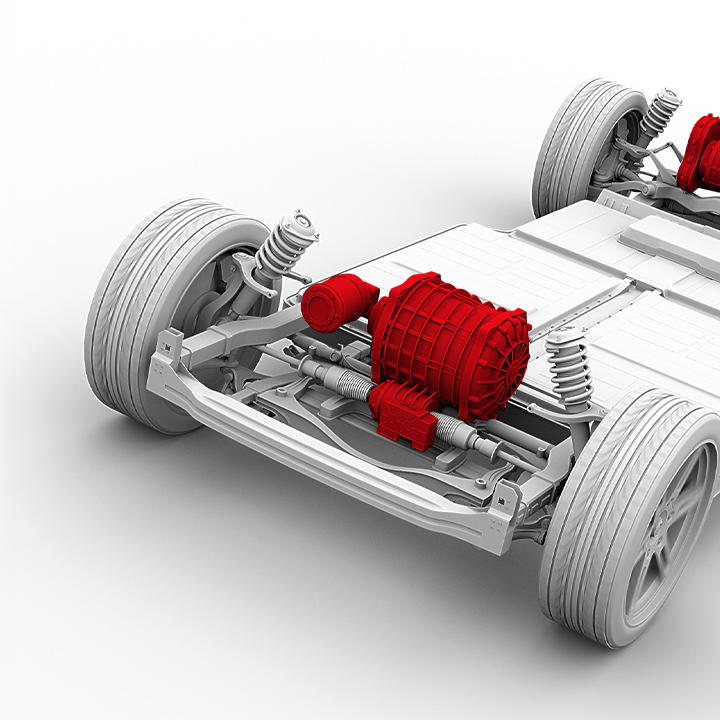

Electric Powertrain

Is your company looking for more efficient and sustainable ways to design and test your electric powertrains and components? Typhoon HIL’s simulated solutions can manage all of your electric vehicle (EV) and e-Mobility testing and validation needs quickly and seamlessly. Built for HIL testing of electric powertrains, our solutions are:

- Down to 200ns simulation time step with 3.5ns digital oversampling

- Interfaces for existing system-level simulators and HIL test bench set-ups

- ASAM XIL compliance guaranteed integration with other automotive test tools

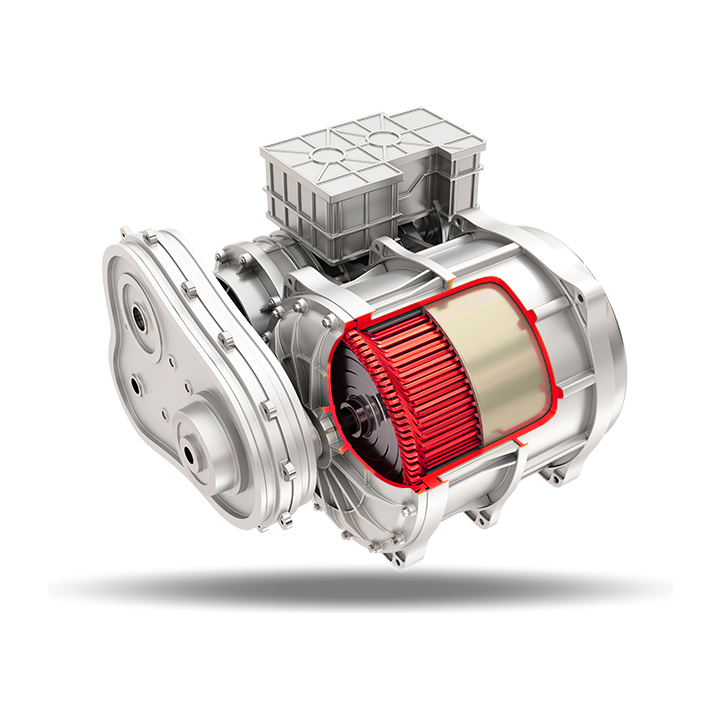

e-Drive

Automotive manufacturers today are under great pressure to find new ways to develop, test, and validate their high-performing electric drive units, despite shrinking budgets and shorter timeframes. If this sounds familiar, Typhoon HIL’s Hardware-in-the-Loop (HIL) solutions can help you overcome industry challenges to improve your testing processes by:

- Full test automation suite, with integration to DevOps processes

- Reduced lag time, so testing is optimized

- True plug-and-play HIL solution

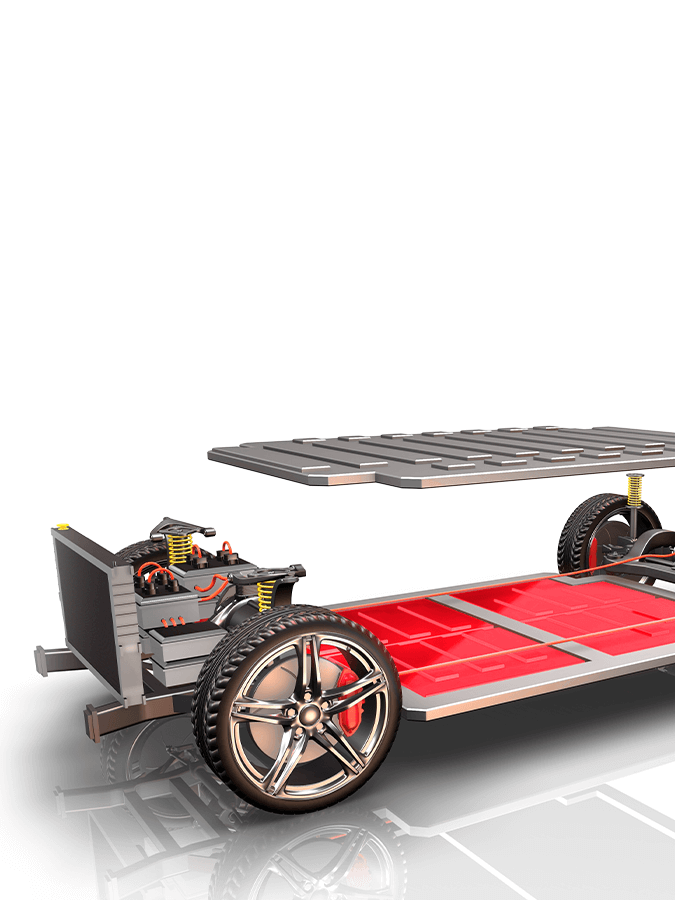

Battery Management System

Our comprehensive toolchain makes it easy to ensure all of the components of your battery management system, controllers, and chargers are at peak performance. This is essential to maximize the lifespan and reliability of your EVs. Recreate a range of faults and errors and delays using our high-fidelity simulations to see how your battery management systems stand up in the real world, and make any changes needed to address any safety hazards proactively. Scale your BMS solution with:

- Cell model running on a real-time simulator with 16x cell emulator channels per box

- Modular design (easy to upgrade system simply by adding more boxes, no need for existing equipment modifications)

- Thermistor and isolation resistance emulators available

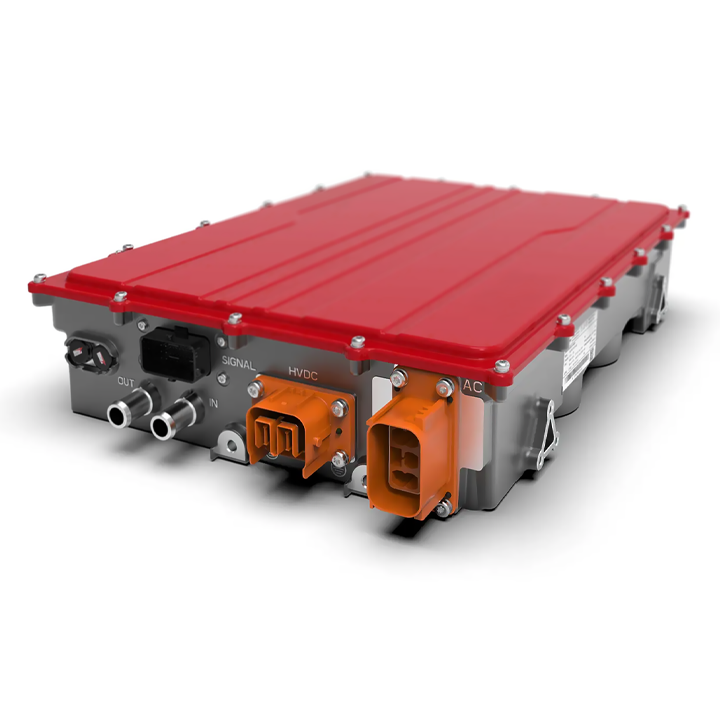

On-Board Charger

Your on-board charger (OBC) plays an essential role in powering your electric vehicles (EVs). Typhoon HIL’s specialized hardware enables your charger to communicate with a variety of external sources to convert AC energy into DC energy to charge your battery system. Our system makes it easy to simulate the charger components and switching capabilities in real-time in order to test these features in the virtual space and make sure they work under a range of conditions in the safest and most reliable way. Moreover, we support your team by:

- Testing for DC fast chargers, and electric vehicles OBC

- Early stage validation of control algorithms and communication protocols

- Simplifies the process of compliance testing with safety and communication standards, such as ISO 15118

EV Charging Stations

Typhoon HIL offers a cutting-edge simulated solution that makes it easy to test your charging station with your EV to ensure everything works together safely and efficiently. Our high-fidelity platform streamlines the process to help you optimize your charging station testing experience.

- DCDC converters simulated with 25ns time step

- Validate communication protocols for different models of EVs and EVSE and test against existing charging standards

- Validate DC fast chargers interoperability with different EVs without the ISO 15118 implementation complexity

- Perform conformance tests in-house, avoiding certification failures and reducing development costs

- Test the integration of the V2G management system with the grid in real-time validating controllers and power converters for bidirectional power flow