Imagine. Empower. Transform.

Engineering the future of digital power with

vertically integrated end-to-end HIL testing solutions.

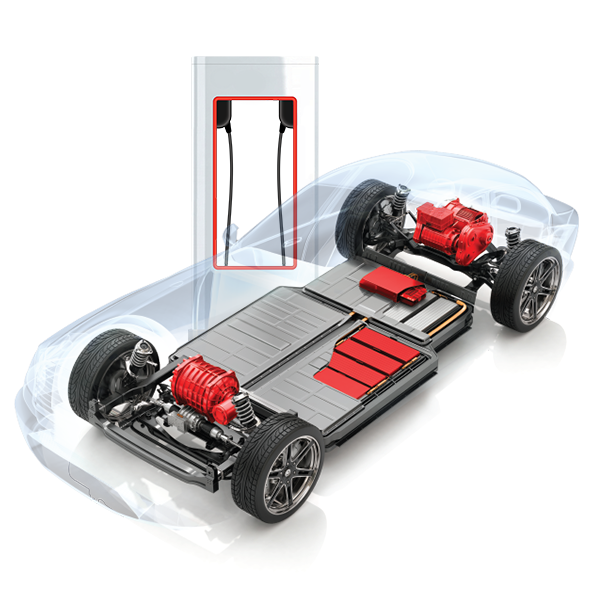

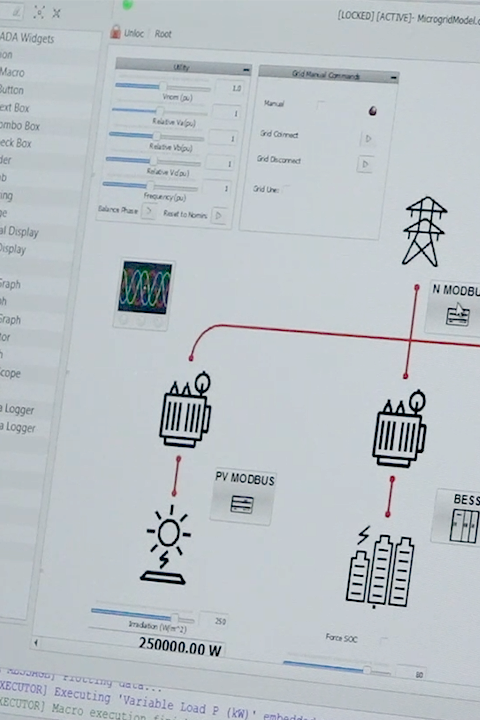

Hardware-in-the-Loop simulation solutions.

Streamlining embedded software design, testing, and lifecycle maintenance with ultra-high fidelity Hardware-in-the-Loop – ensuring you peace of mind.

Best-in-class HIL simulators.

Supporting a range of HIL system setups and testbeds, we offer vertically integrated HIL simulators, a spectrum of plug-and-play HIL interfaces, and a library of HIL Compatible devices. Combine our hardware with our flagship software and our engineering services to outrun and outperform your competitors.

Products

TechDay 2024

Join us in Novi Sad, Serbia on June 27-28, 2024.

*Enhance TechDay with our Pre-Conference HIL Essentials Training on June 26th.

Empowering companies to help create a sustainable future.

Knowledge Center

Dive into our cutting-edge content and engaging resources for indispensable learning, research, and innovation.

Discover. Share. Evolve.

Academic & Research

Enrich your HIL experience from day one, explore our on-demand learning, teaching platform, and magnify your research impact.

Learn. Research. Teach.

Services

Explore our comprehensive range of top-quality services designed to meet your unique needs, achieve your goals, and embrace your vision.

Dedication. Commitment. Excellence.