Introduction | The current landscape of EV motors

Motors built with permanent magnets (PM) have been widely considered the state-of-the-art solution for electric vehicles (EV). Currently, these motors are used in more than 90% of EVs due to their high efficiency and power density.

The magnets used to build these motors are made of heavy rare-earth elements such as Neodymium, Terbium, and Dysprosium. Rare-earth elements have complex extraction processes in comparison with other minerals. This results in price volatility and a limited supply chain, bringing some specific challenges to the manufacturing process of PM motors. In response to this, developing rare-earth-free electric motors which can achieve higher speed, power density, and voltage at a lower cost has been a rising trend in the e-Mobility industry.

e-Mobility Trends | Motor technologies free of rare-earth metals

With the need to replace PM-based motors, the automotive industry is exploring different technologies that are readily available and environmentally friendly. Some rare-earth-free motors that have been widely researched are switched reluctance motors (SRMs) and rare-earth-free internal permanent magnet synchronous motors (IPMSMs).

Switched Reluctance Motors (SRMs)

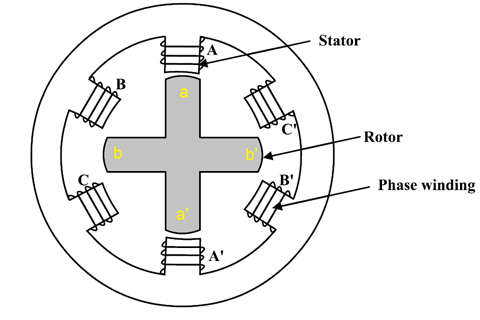

SRMs feature stators that contain windings, while the rotor itself is simply made of steel shaped into salient poles. These motors work on the principle of variable reluctance. The rotor tends to align to the lowest reluctance lane, so a position sensor is used to measure the angle of the rotor shaft and inform the controller to switch the stator windings.

Compared to induction motors (IMs), PMSMs, and brushless DC motors, SRMs have increased efficiency, reliability, a high constant power speed ratio, and are resistant to high temperatures (due to the lack of magnets on the rotor). Moreover, the simple and rugged structure of these motors enables faster and cheaper manufacturing, reduced weight, and smaller control complexity.

The benefits of SRMs make them very appealing for EV applications. However, these motors also have some disadvantages and design challenges. Since the stator and rotor have salient poles, these motors produce increased torque ripple, which causes undesirable acoustic noise and vibration. Therefore, controlling each winding and precisely tracking the rotor position to compensate for the variable reluctance is challenging for manufactures.

Rare-Earth-Free IPMSMs

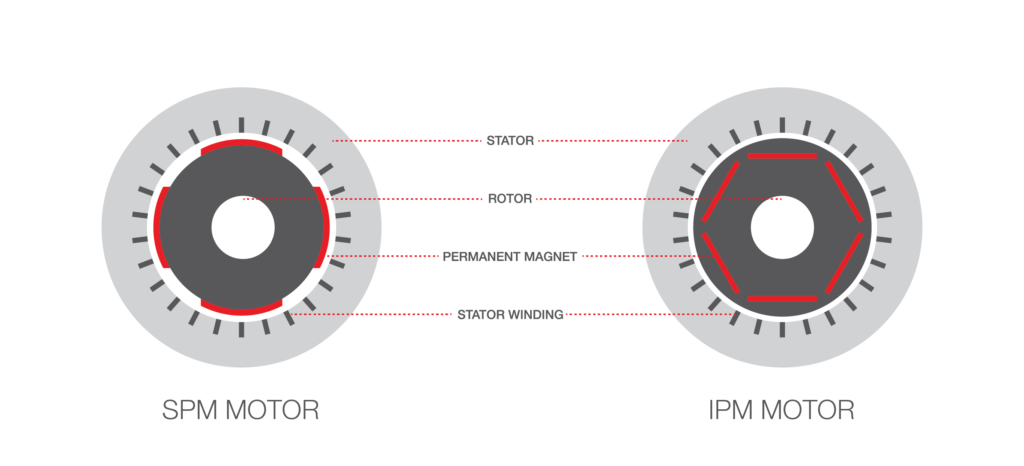

Permanent Magnet Synchronous Motors (PMSMs) are divided into two types: in surface type (SPMSMs), where permanent magnets are attached to the exterior of the rotor surface, and internal type (IPMSMs), where the rotor is embedded with permanent magnets.

Internal magnets are more secure mechanically and magnetically than surface magnets, which makes them a more attractive and reliable solution for e-Mobility applications. These magnets are more frequently used for prolonged constant power operation and produce larger flux densities in the air gap.

IPMSMs based on Neodymium Iron Boron (NdFeB) are the most common type of motor used in EVs. However, due to the issues related to the usage of rare-earth metals, alternative magnets, such as ferrite-based permanent magnets, have been a target of research and development.

Ferrite PMs are mainly composed of ferric oxide, which is widely available around the globe. These magnets have a lower environmental impact, reduced cost, and are also simple to produce. Furthermore, they present excellent resistance to corrosion and great electric resistivity, which minimizes eddy current losses.

Despite their advantages, ferrite magnets have a much lower residual induction field and maximum energy product than NdFeB magnets. To achieve the same performance as with rare-earth magnets, the volume of ferrite magnets needs to be higher, which in turn increases weight and volume of the motor. For this reason, developing efficient motor controls is even more critical when trying to make ferrite motors cost effective.

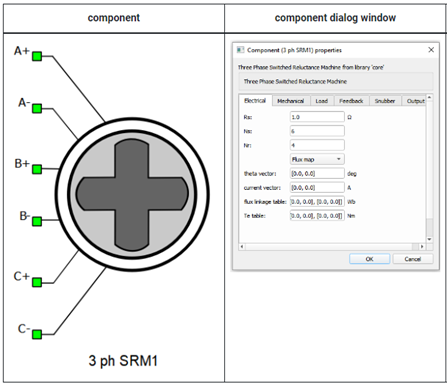

HIL Benefits | Simulate the future of EV motors

Typhoon HIL provides a full library of pre-packed models of electric machines, such as the SRM model presented in the figure below, which you can use to simulate future technologies of rare-earth-free motors. These HIL solutions help save development costs and time due to easy model integration and test automation capabilities, but also reduce risk due to improved product targeting and reduced prototype failures.

From the automation perspective, you can create and execute automated tests taking advantage of the integrations with third-party tools, such as ECU-TEST via our ASAM XIL-MA compliant API.

Moreover, you can benefit from an intuitive user interface to create tests, define workflows, and track progress in real time. Typhoon toolchain also enables you to create test reports automatically, which can rapidly help you gather invaluable information for the control validation process.

Credits

Authors | Cassiano F. Moraes, Heitor J. Tessaro

Visuals | Milica Obradovic, Karl Mickei

Editors | Debora Santo, Sergio Costa