Introduction

In the “Accelerate xEV Motor Drive ECU Development and Testing with HIL” webinar, Infineon Technologies, Infinitum, and Typhoon HIL partnered to discuss the challenges engineering teams face in motor drive electronic control units (ECUs) development and testing, and demonstrate how HIL simulation provides a safer, faster, and more comprehensive path for controller validation.

Challenges in Validating EV Motor Drive Controls

Developing reliable EV motor drive controls starts with ensuring that algorithms perform consistently across the full range of operating conditions. Controllers must manage disturbances, handle transients, and enforce safety protections long before being deployed on physical prototypes. Traditional workflows relying heavily on bench setups or real hardware often leave gaps in early validation. Ryan Collin, Senior Power Electronics Engineer at Infinitum, described how HIL simulation accelerates this process:

This is where the value of a HIL system comes in. We can quickly test performance at different points of operation, steady state and transient, and then verify that safety features are functioning as expected, all before reaching the final hardware test bed.

Ryan Collin

Senior Power Electronics Engineer

Infinitum

Another critical step is selecting a suitable microcontroller, which determines whether the platform can meet both current project requirements and future functional demands. Key considerations include I/O capacity, ADCs, PWMs, memory, clock frequency, and cost.

Ensuring the robustness of safety features before hardware testing is also essential. Physical prototyping often has limitations; hardware may be unavailable in the early stages, and reproducing fault scenarios can be unsafe, risking damage to expensive equipment. Lizhi Qu, Principal Controls Engineer at Infinitum, highlights how HIL accelerates the initial testing stage of the controller.

If we only consider software tests for the controller, it can be pretty fast with the help of the Typhoon HIL team. Most likely it only needs several days or weeks.

Lizhi Qu

Principal Controls Engineer

Infinitum

Real-Time Simulation as the Bridge Between Software and Hardware

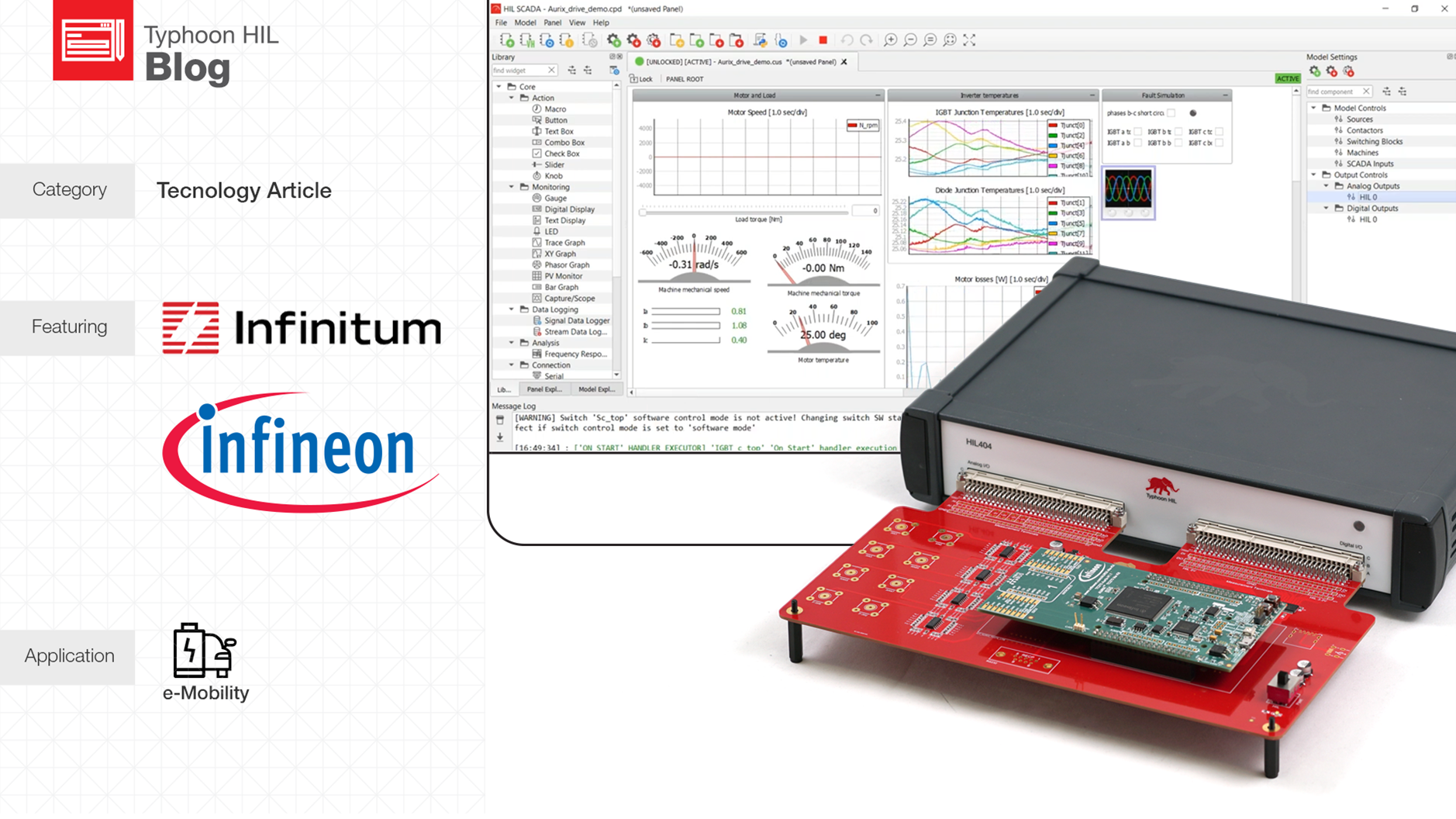

Controller performance depends on both algorithms and hardware, and bringing them together for testing is where Typhoon HIL is critical. Typhoon HIL and Infineon Technologies have collaborated to provide a fully integrated, real-time development and testing environment for EV powertrain systems. The solution combines Typhoon HIL’s ultra-high-fidelity simulators, such as the HIL404 and high-capacity HIL606, with Infineon’s AURIX™ TC3x and TC4x automotive microcontrollers (MCUs). Robert Valascho, Director of Field Application Engineering at Infineon Technologies, explained how the upcoming TC4 series is designed to meet the new demands of e-Mobility:

There’s such a push towards electrification speeds that you need new ways to handle them. The TC4 series addresses not only the peripherals but also the control side, enabling advanced mathematics for evolving motor and power conversion requirements.

Robert Valascho

Director of Field Application Engineering

Infineon Technologies

This approach creates a streamlined workflow where the complete powertrain is modeled in the Typhoon HIL schematic editor. High-fidelity models allow inverter characteristics to include switching and conduction losses, or turn-on/turn-off delays. For motors, the simulation can include non-linear effects such as magnetic saturation, spatial harmonics, and iron losses, with parameters derived from lab measurements or imported directly from finite element analysis (FEA) software like JMAG.

We are mainly focusing on building a system that’s easy to configure and deploy and maintain throughout the whole product life cycle, that’s easy to share further down the line and maybe even reuse in future projects.

Petar Gartner

Director of HIL Solutions

Typhoon HIL

The real Infineon controller connects directly to the HIL Simulator via a dedicated Infineon TriBoard Interface Card, a plug-and-play solution that enables comprehensive software testing long before the final hardware is manufactured. From the controller’s perspective, it operates as if connected to a real motor, while engineers observe simulated currents, voltages, and temperatures in real-time through Typhoon’s SCADA interface.

A Streamlined Workflow

Using Typhoon HIL’s solutions, engineers can:

- Validate control algorithms under both steady-state and transient conditions.

- Simulate high-fidelity inverter and motor behavior, including nonlinearities and thermal effects.

- Safely and repeatably test dangerous scenarios, such as short circuits.

- Automate testing and reporting through open APIs, ensuring consistency across the product life cycle.

By integrating directly with Infineon’s AURIX™ MCUs, this workflow bridges the gap between software development and physical deployment. Engineers can start testing on evaluation boards long before final hardware is available, reducing costs and time-to-market.

Conclusion

The collaboration between Infineon, Infinitum, and Typhoon HIL demonstrates how real-time simulation is transforming EV motor drive development. By shifting validation earlier in the development cycle, engineering teams can iterate faster, cover more test cases, and build confidence in their designs well before physical prototypes exist. HIL simulation enables teams to address evolving industry demands and deliver reliable, high-performance motor drive systems to market faster.