Introduction

Sansha Electric Manufacturing Co., Ltd. (SanRex) is a manufacturer of power semiconductors and industrial power supply equipment in Japan. Guided by the purpose of advancing society through power electronics and creativity, Sansha Electric contributes to industries worldwide. Originating in Osaka, Japan, the company continues to drive innovation with its power converter technology at the core of its solutions. By adopting Typhoon HIL’s Hardware-in-the-Loop (HIL) solutions, they managed to dramatically accelerate their control software development workflow.

Jun Sugiyama, Hironobu Kiyama, Akihiro Fujita, and Isamu Sugiyama visited and interviewed Typhoon HIL users at their Technology Development Department, Mr. Miyake, Mr. Yamamoto, and Mr. Haku, so you could learn more about their first-hand experiences with HIL technology in this blog article.

Please, tell us about your team’s work at your department.

Mr. Yamamoto: We are developing inverters and simulator power supplies using various energy sources. The main applications are for storage batteries, fuel cells, and solar cells.

How familiar are you with the HIL Technology before it was introduced to your department?

Mr. Yamamoto: I didn’t know about Controller Hardware-In-the-Loop (C-HIL), but I did know about Power Hardware-In-the-Loop (P-HIL), because I saw it at a customer’s site.

Mr. Haku: I had heard the term HIL many times before, but I didn’t have a clear understanding of what it truly was.

Mr. Miyake: I wasn’t aware of it until I joined my current department.

What influenced your decision to adopt Typhoon HIL in your work?

Mr. Yamamoto: Before implementing Typhoon HIL, we had two major challenges. First, the scope of digital testing is narrow before performing an integrated test of the digital part with the power system. The second is that it wasn’t possible to perform the hardware and software design in parallel, so it had to be done sequentially. While some parts were handled concurrently, most of the work was performed in a linear, step-by-step manner, and this delayed progress.

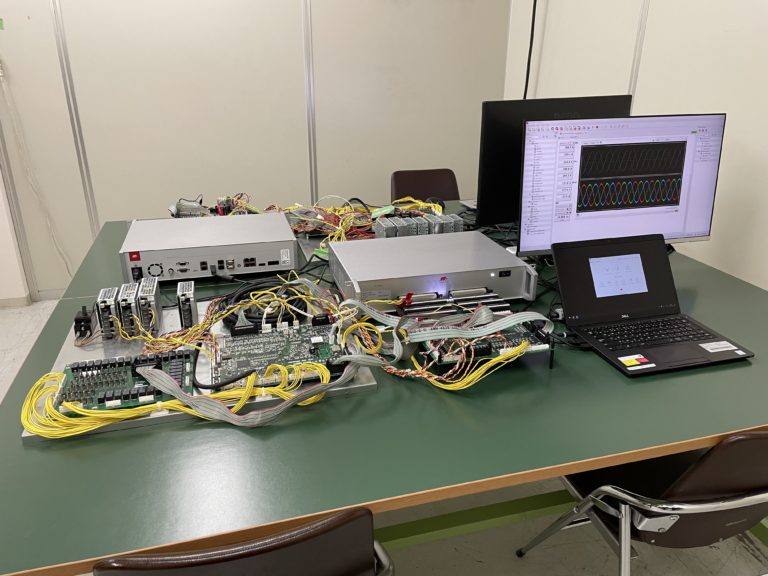

Mr. Haku: Before implementing Typhoon HIL, we used circuit simulators to debug real software. When using a circuit simulator, it can take a considerable amount of time to run simulations and check the results. In particular, when performing complex simulations, it could take up to half a day to obtain analysis results.

One of the biggest advantages of using Typhoon HIL is that results which previously took half a day to analyze with a circuit simulator can now be reflected in real time.

Mr. Haku

Mr. Miyake: Prior to using Typhoon HIL, debugging was performed only after both hardware and software were completed. Issues encountered during testing could result in damage to the hardware, necessitating its reconstruction and subsequent re-verification. This process often involved multiple modifications and repairs, which increased the time required for development.

Why did you choose Typhoon HIL?

Mr. Yamamoto: First, we couldn’t find any other C-HIL systems available at a reasonable price. Second, based on the hardware specifications, we felt confident that a carrier frequency of around 100 kHz would be sufficient for the system to operate reliably as a HIL platform. While there were HIL solutions available for automotive applications, it was quite difficult to find one suitable for power converters. Frankly speaking, we found no other HIL manufacturer with device specs that matched our requirements, and since Typhoon HIL was the only platform capable of fulfilling our objectives, it was effectively our sole choice.

What applications do you use HIL testing for?

Mr. Yamamoto: We utilize Typhoon HIL in systems that include a Power Conversion System (PCS) combined with PV and batteries, or fuel cells paired with energy storage. It is effectively applied to integrated configurations of converters and overall systems, as well as to emerging technologies such as grid stabilization.

Mr. Miyake: Typhoon HIL is utilized to test power conditioners designed for grid stabilization, particularly under conditions where grid-side voltage and frequency are intentionally altered. In the future, we plan to investigate how these power conditioners behave in response to such fluctuations.

What are the most important benefits of Typhoon HIL for you?

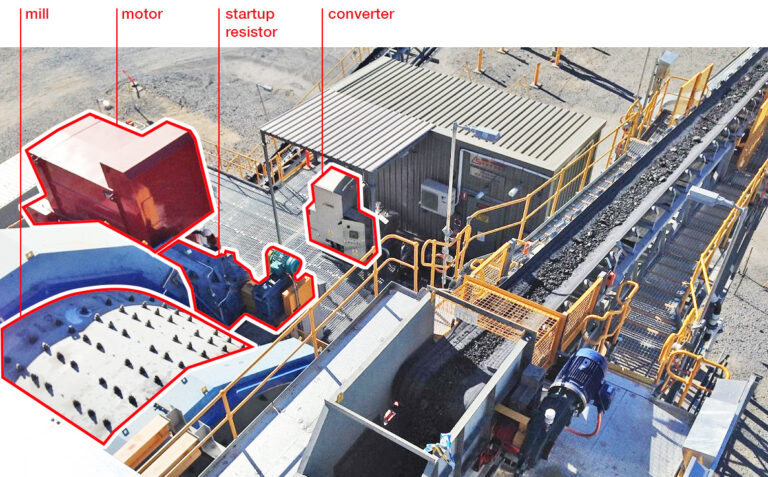

Mr. Yamamoto: The most significant benefit of using Typhoon HIL has been the reduction in development time. It also allows us to visually observe system behavior, making it easier to determine whether the software is functioning correctly. Previously, we had to travel frequently between our development site and the factory to verify large equipment, which was in a remote area. Now, much of the verification can be done locally, which has brought substantial advantages.

In the past, we needed to visit the factory to test the software in combination with actual hardware, but once there, we often lacked a proper debugging environment. With the introduction of Typhoon HIL, most of the testing can now be completed in the lab, and only final validation needs to be done at the factory. Overall, the process has been shortened by roughly 30 to 40 percent. I believe our workload has dramatically reduced.

Mr. Haku: One of the biggest advantages of using Typhoon HIL is that results which previously took half a day to analyze with a circuit simulator can now be reflected in real time. As Mr. Yamamoto mentioned earlier, we still perform final product verification at the factory. In the past, we would observe hardware engineers operating the equipment and, when issues arose, analyze logs one by one. The amount of visible information was limited, and what we could extract on-site was often constrained. Software engineers had to travel to the site to rewrite and test the software directly, which sometimes led to equipment failures.

With Typhoon HIL, however, we can reproduce the same conditions based on reports from the factory, analyze the issue remotely, verify the fix, and update the software, all without having to be physically present. This allows us to run analysis and debugging in parallel with factory operations. I believe this is a key reason why we’ve been able to significantly reduce the overall development time.

Mr. Haku

Additionally, grid interconnection testing for power conditioners has become increasingly complex and large-scale. Conducting these tests with actual hardware takes a great deal of time, manpower, and effort to set up the necessary equipment. I’m currently working on automating the entire grid interconnection test process using TyphoonTest IDE. This approach eliminates the need for physical setups, allowing us to run tests automatically overnight and review the results the next morning. While HIL-based tests may not necessarily directly qualify for certification, they enable us to run all necessary test cases efficiently and identify potential issues in a much shorter time.

Mr. Yamamoto: As I mentioned earlier, for cases where actual hardware data is required, conducting tests on the physical equipment is of course essential. However, the key issue is how we can ensure that the software is absolutely not the cause of any malfunction. If the software operates correctly within the HIL environment, and there are no issues with the hardware, we can reasonably conclude that the system will function as intended. Additionally, there are discussions about future certification processes where validation through both actual hardware and HIL-based testing may be considered acceptable.

What will you do with Typhoon HIL in the future?

Mr. Yamamoto: We’ve already started taking steps, but our basic approach is to conduct all tests equivalent to JET’s grid interconnection tests using Typhoon HIL. Secondly, we’re focusing on limit testing, for example, verifying through software how the system behaves when it exceeds its rated capacity. Thirdly, if possible, we’d like to perform tests that involve injecting high-frequency signals into the feedback channels to evaluate system response.

Mr. Haku: I’m currently working on automating grid interconnection testing, and I believe expanding this effort as much as possible is key. One major advantage of Typhoon HIL is that everything can be controlled using Python. Ideally, we’d like to reach a point where even documentation generation and related tasks are fully automated through Python. Ultimately, my goal is to establish a continuous integration development process where, whenever the software is updated, tests are automatically executed.