Introduction

Energy networks worldwide are evolving to become increasingly more decentralized, fueled by new developments in many sectors: Industry 4.0, Distributed Energy Resources (DERs), electric vehicles (EVs), and more. This means a greater need for robust local control and storage systems to avoid dangerous disruptions or blackouts. These factors are driving innovation, particularly in two areas: new power electronic controllers for energy storage and DERs, and new system-level control architectures that can control microgrids effectively in a wider range of conditions.

New technologies mean new tests, particularly when nanoseconds can be the difference between stability and failure. Practicing power engineers have been rapidly adopting Hardware-in-the-Loop (HIL)to perform real-time, high-fidelity validation of new devices as a way to address these needs. The use of HIL to connect hardware devices with software models, in particular, has grown, thanks to the exponentially lower testing costs and faster testing speed it provides. Critically, new developments in test automation and experience in equipment modeling are now allowing system integrators to test their control schemes with HIL testing as well.

What does Hardware-in-the-Loop mean?

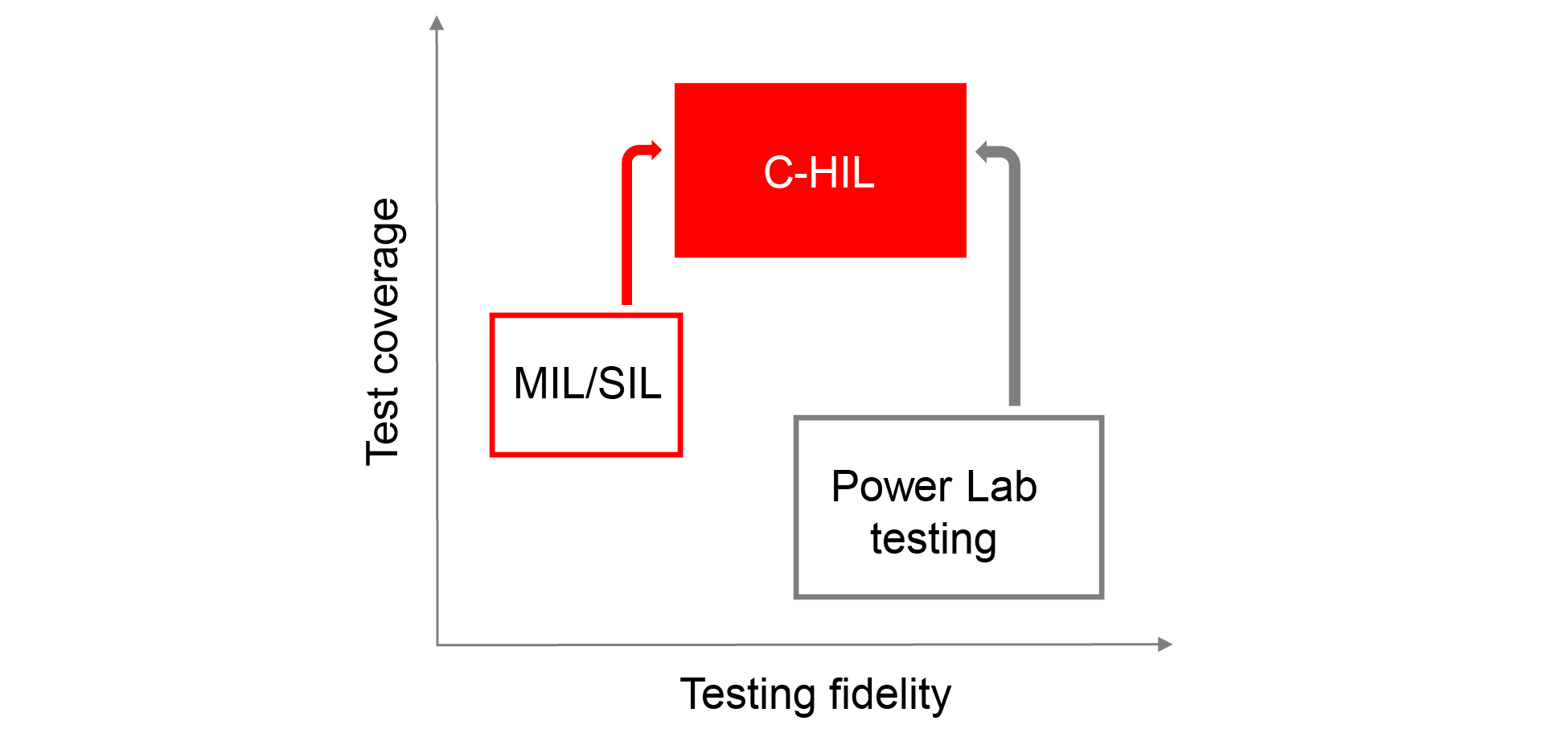

HIL means that there is a physical device connected to a real-time simulation. It can be a piece of power hardware or it can be a piece of the controller hardware. HIL simulation with power hardware is often referred to as Power HIL (P-HIL). We call HIL simulation where the controller hardware is connected to the real-time simulation C-HIL.

Thanks to advances in field-programmable gate array (FPGA) processor technology, commercial C-HIL test systems with analog sampling rates as low as 200 ns and digital input Gate Drive Signal (GDS) oversampling as low as 3.5 ns have become commercially available.

What is the C-HIL approach, and how to use it?

The C-HIL test method is the test procedure where the performance of the physical control system (hardware, firmware, and software) is tested against a mathematical model, simulated in real-time on the C-HIL platform. This approach has been used for decades in the automotive and aerospace industries as the method of choice when testing sophisticated control systems. By connecting controllers to the virtual plant model, simulated in real-time, they are able to test operating conditions that are hard and/or impractical to test in the lab in addition to being time-consuming and unjustifiably expensive.

These advantages have clear impacts on the reliability and quality of the performance systems under test. For this reason, component manufacturers that adopt and commit to the use of model-based HIL testing and validation can even qualify for a HIL Tested certification, which shows that the product performance and quality have been validated in a high-fidelity environment.

The main downside to the C-HIL approach is that integrating external controllers may require a dedicated signal conditioning interface between C-HIL device and the control system under test in order to properly connect the two, but the cost of this does not come close to the costs of building a full power lab.

How do the controller and model connect?

Under traditional P-HIL methods, simple power cables would be wired directly from the elements of the power system to the controller in order to test the real power performance. With C-HIL, the power flows occur within the model itself, meaning it is important to have an interface that allows the controller to “feel” as if it were controlling real power flows.

Thanks to years of experience working with key power control hardware manufacturers, Typhoon HIL has several off-the-shelf controller interfaces that let you perform C-HIL testing right out of the box. Controllers that can be connected for C-HILtesting right out of the box are recognized by their HIL Compatible certification, which ensures that:

- A controller model is developed in the Typhoon HIL Control Center software.

- A pre-built interface for the HIL has been developed or is built-in to the controller.

- Controller version management has been implemented to ensure the models and interfaces are up to date.

Inverter manufacturers and system integrators that have already developed HILCompatible controllers include ABB, EPC Power, Schneider Electric, and Woodward, among others.

How can I do tests even faster?

Performing tests for new microgrid deployments often requires complicated test conditions that have to be repeated through many different validation scenarios. Planning these tests in advance can be very time-consuming, and some firms even hire dedicated Test Automation Engineers in order to automate these critical tests.

New tools like the TyphoonTest Automation Framework and TyphoonTestIDE allow Power Engineers to create powerful test scripts with detailed automated reports directly from the software interface, with little to no coding knowledge required. This means tests can be performed more quickly and with less overhead, freeing up engineers to devote significantly more time to designing a reliable system, instead of developing the testing process itself.

What does this mean for microgrid testing?

By using C-HIL for power electronics testing, device manufacturers can more easily ensure that their existing or new power electronics equipment is proven and HILTested for the unique challenges that microgrids provide. Making these controllers HILCompatible then allows System Integrators to simulate multiple options for system-level control using proven devices in a high-fidelity setting – drastically reducing both the costs and risks of designing and implementing new microgrids.

Credits

Author | Sergio Costa

Visuals | Karl Mickei

Editor | Debora Santo