Introduction

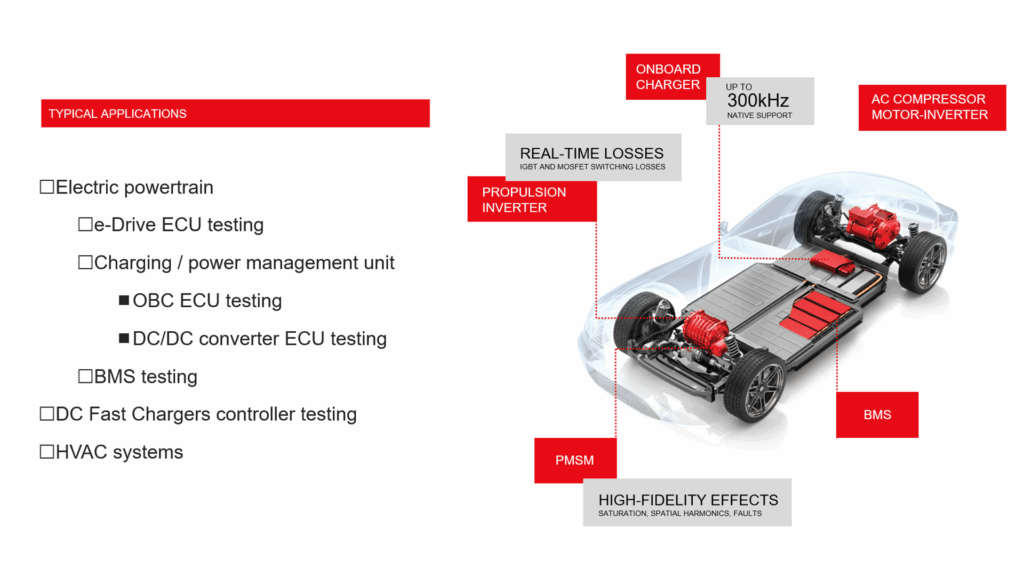

As electric mobility advances, companies like DeepDrive are pushing the boundaries of e-Drive system design. Their dual-rotor radial flux motors, built for both central and in-wheel applications, aim to extend vehicle range by approximately 20%, reduce material use, and streamline manufacturing. But to meet demanding OEM timelines, DeepDrive had to rethink how they validate and deploy these complex systems.

Challenges in Validating DeepDrive’s e-Drive Architecture

In e-Drive testing, control system validation is a bottleneck. Traditional development workflows, which rely on Model-in-the-Loop (MIL) simulations, lab benches, and motor emulators, offer limited fidelity and tend to slow down the iteration process. These methods often depend on hardware availability, making it challenging to test early or frequently, which can delay the product’s market launch time. Reproducing edge-case scenarios, such as semiconductor failure or sensor faults, can be unsafe or impractical in a set up with real power flow.

According to Christopher Römmelmayer, Software and Control Engineer at DeepDrive, they needed a better way to test early, iterate faster, and validate thoroughly, before power hardware was even available. To break through these constraints, DeepDrive needed a way to test their systems with high fidelity, reuse firmware across development stages, and accelerate iteration, without compromising safety or accuracy.

It usually takes two years to develop 90% of the control system, and three years to get to a running test vehicle. That’s just too long in our industry.

Christopher Römmelmayer

Software and Control Engineer

DeepDrive

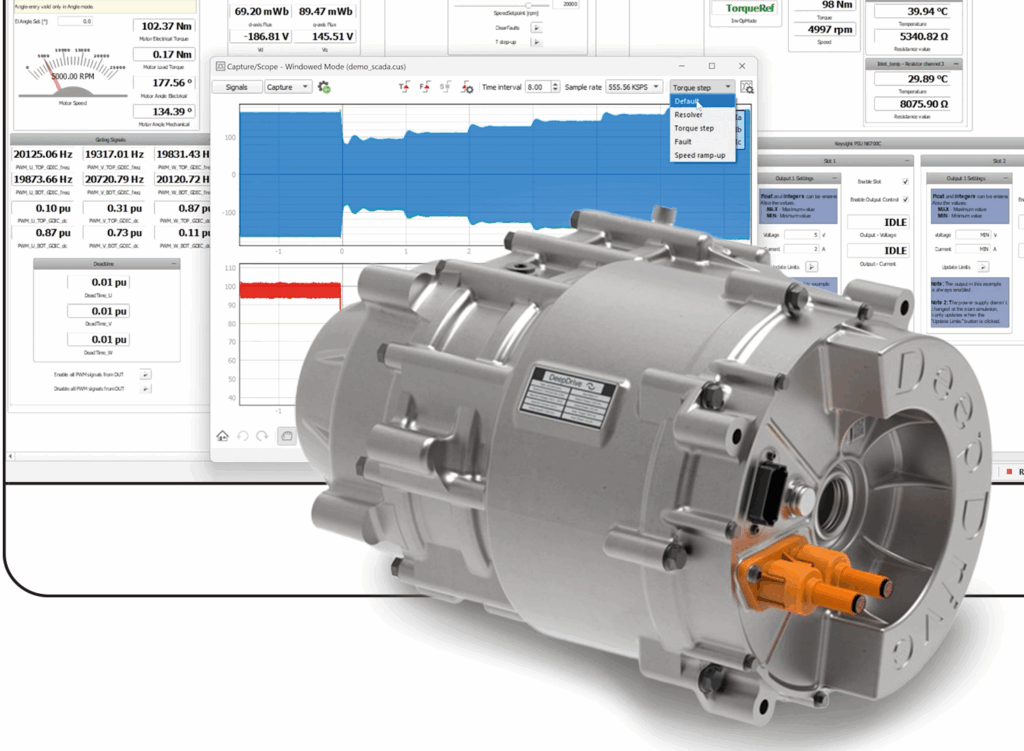

A New Approach with Typhoon HIL’s Real-Time Simulation

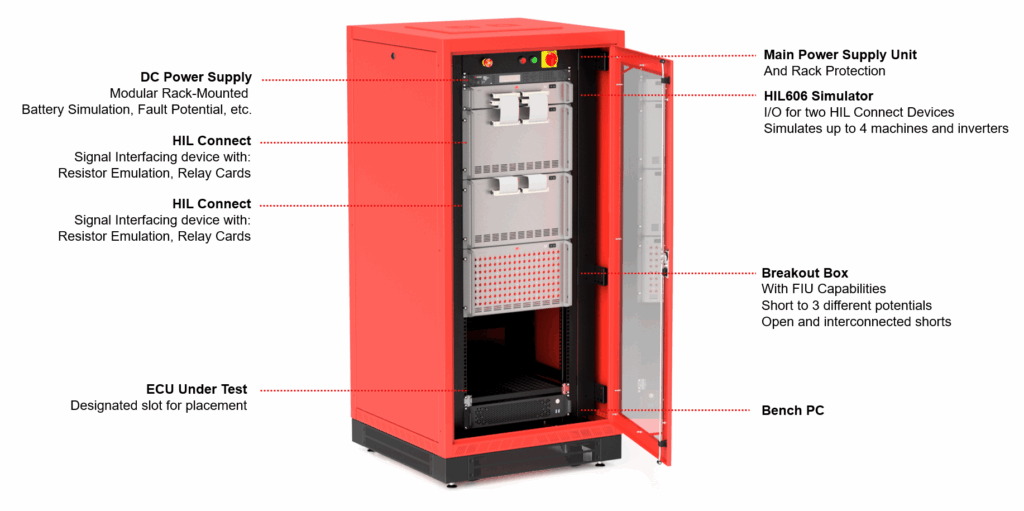

To meet the needs, DeepDrive adopted Typhoon HIL’s e-Drive Testbed, a comprehensive real-time simulation platform. The system included:

- HIL404 Simulator – real-time simulator

- HIL Connect – for signal interfacing

- Breakout Box – for physical fault injections

- DC and Main Power Supply units

- Vertically integrated software toolchain – supporting rapid model development and test automation

Together, this enabled execution of Typhoon’s “HIL in a Day” approach, a practical demonstration of how quickly and effectively a complete HIL test environment can be brought online.

Results within 48 hours for DeepDrive included:

- Connected control PCB in the HIL testbed.

- Configured and deployed a nonlinear motor model that, when combined with the operational control system, exhibited torque output within ±5% of a real motor, demonstrating high level simulation fidelity.

- Emulated NTC sensor inputs via resistor emulator cards in HIL Connect.

- Most significantly, the same firmware used in the HIL simulation environment was deployed without modification to bench and vehicle setups, preserving consistency, avoiding duplication, and reducing development risk.

Benefits from Faster Validation and Greater Coverage

The impact of this new approach was immediate. By adopting real-time HIL simulation, DeepDrive reduced its control validation timeline by over 12 months. Simulation scenarios, such as load torque dynamics, encoder dropouts, and sensor failures, can now be tested in real-time and under safe, repeatable conditions. High-speed signal analysis, such as PWM deadtime duration measurement, became possible with nanosecond-resolution tools, enabling detailed waveform validation and precise timing diagnostics.

Rather than centralizing resources around a single test system, DeepDrive installed multiple testbeds that run in parallel. This allows teams focused on controls, integration, and system testing to work simultaneously without hardware contention. Engineers, whether on-site or remote, can securely access simulations and utilize integrated tools for testing automation. Additionally, full API coverage in the Typhoon HIL toolchain enables seamless integration with existing tools for calibration and debugging to further streamline the validation step.

A Future-Ready Development Workflow

In today’s fast paced market where innovation and speed are critical, the integration of the Typhoon HIL testbed enables DeepDrive to bridge groundbreaking design with real-world deployment. The Typhoon HIL platform empowers engineers to validate control performance well before physical prototypes are built, significantly reducing development time and enhancing safety. Vincent Berger, Business Development Specialist at DeepDrive, highlights this transformative impact.

You can’t scale innovation alone. Our partnership with Typhoon HIL helped us validate faster, iterate more safely, and bring our next-gen drives closer to production readiness.

Vincent Berger

Business Development Specialist

DeepDrive

Typhoon HIL’s vertically integrated solution, encompassing hardware, software, and services, enabled DeepDrive to shift from time-consuming bench tests to agile, automated workflows that match the pace of modern EV development, eliminating manual inconsistencies and ensuring that each update is systematically validated.