Blog

How DeepDrive is Accelerating e-Drive Development with HIL

July 24, 2025

As the race to innovate in electric mobility intensifies, DeepDrive is redefining how e-Drive systems are developed and validated. With their dual-rotor radial flux motors promising increased range and efficiency, the team needed a faster, safer way to test control systems before physical hardware was even available. By adopting Typhoon HIL’s real-time e-Drive testbed, DeepDrive accelerated validation, re…

Optimizing e-Drive ECU Testing with Comprehensive Turnkey HIL Solutions

October 17, 2024

In the fast-evolving world of e-Drive ECU testing for electrified vehicles, comprehensive turnkey HIL solutions are key to optimizing performance and ensuring system reliability. Through expert panel discussions, live demos, and an interactive Q&A session, Typhoon HIL’s recent webinar shed light on the challenges and innovations in this space. Discover more about how these e-Drive HIL testing solutions can …

Developing Innovative Rare-Earth-Free Motor Topologies with HIL

June 21, 2023

Permanent magnet (PM) motors, using heavy rare-earth elements like Neodymium, Terbium, and Dysprosium, have been the go to choice for electric vehicle (EV) motors due to their efficiency and power density. However, complex extraction processes and limited supply chains have led to price volatility. To overcome these challenges, the e-Mobility industry is increasingly focusing on developing rare-earth-free e…

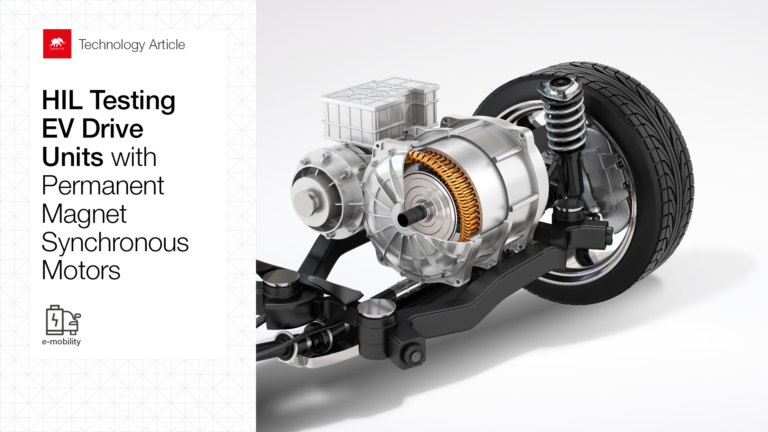

HIL Testing EV Drive Units with Permanent Magnet Synchronous Motors

December 1, 2022

The evolution of Electric Vehicles (EVs) is directly related to the development and use of more efficient and reliable components. Permanent Magnet Synchronous Motors (PMSMs) provide higher efficiency and power density in a smaller frame, which contributes to achieving targets set forth for EVs. This article outlines the benefits of PMSMs in the e-Mobility sector and how Typhoon HIL solutions can help test …

Fuji Electric’s Railway R&D Center Tests New Trains with HIL

June 8, 2022

How the Fuji Electric evaluation process led to Typhoon HIL solution adoption. Key challenges in traction applications before introducing HIL testing. Main advantages of HIL testing electric train propulsion inverters and motor drives.

Danfoss Drives Streamlines Customer Support with Typhoon HIL Solutions

February 25, 2022

Danfoss Drives leverages Hardware-in-the-Loop (HIL) technology to provide faster customer support and ensure high-quality drive performance. Engineers appreciate the ease of use of HIL systems, which they value most for their efficiency. HIL enables engineers to effortlessly develop machine-agnostic drive control software, streamlining the development process. Learn more about the way Danfoss Drives reaps …

HIL simplifies the customer support process at Danfoss Drives

November 15, 2021

Blog Highlights

Having the same HIL system as a tool streamlines cross-team coordination and speeds up customer response time.

With Typhoon HIL, Danfoss’ customer response time went from one or two weeks down to a few hours.

For Danfoss customers, HIL Tested means fast customer response times.

What Makes HIL Solutions a Unique Tool for Danfoss Drives Engineers

October 25, 2021

After adopting Scrum and Agile methodologies, Danfoss Drives streamlined its development process by implementing Typhoon HIL for iterative testing. This approach allowed them to develop in smaller sprints and use a HIL infrastructure that was ready to go straight out of the box. As a result, Danfoss Drives significantly reduced the time required for validation tests of software controls. To learn more about…

HIL Drives Frontline Customer Support at Danfoss Drives

September 22, 2021

Danfoss Drives achieved significant improvements in speed, cost savings, and quality by using Hardware-in-the-Loop (HIL) testing. With HIL simulation, tasks that typically required weeks in the lab were completed in just a few days, allowing for efficient software adjustments that met customer expectations. This approach not only enhanced operational efficiency but also provided a superior customer experien…

Honda R&D Streamlined Control Development and Testing with Typhoon HIL

August 7, 2020

HIL technology streamlined Honda R&D’s control development and testing, addressing the increasing complexity of embedded systems that demand more development effort and time. Its intuitive, easy-to-use interface allows first-time users to begin simulating immediately, while fast model compilation with HIL significantly reduces verification time. Read the blog to learn more about how HIL is transforming the …

{{text}}