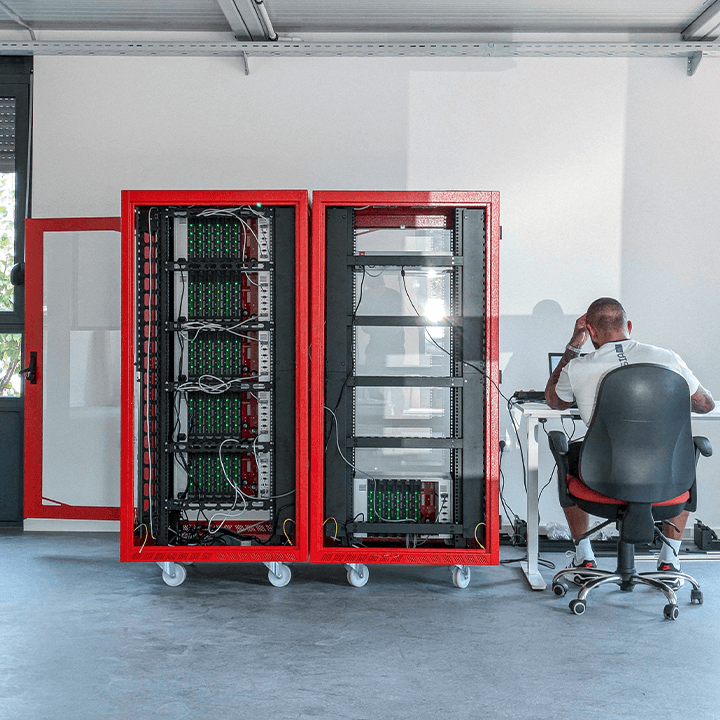

BMS HIL Testbed

Discover our BMS HIL Testbed, featuring the ideal combination of battery emulation hardware and real-time simulation software. It’s designed to help you seamlessly validate next-generation battery management systems for electrified transportation.

Avoiding the fault prone multi-vendor platforms.

Say goodbye to the headaches of managing multiple vendors and the risk of faults that come with them. With our BMS HIL Testbed, you get a reliable, turnkey platform that’s been meticulously engineered to avoid these pitfalls. From scalable Smart Cell Emulators to detailed cell models, everything you need is under one roof. Whether you’re working with 60 V, 400 V, or 800 V systems, our testbed adapts to your needs, offering all the essential signals and communication protocols—DC Pack Voltage, Shunt Emulation, Thermistor Emulation, and CAN/CAN-FD. It’s not just a tool; it’s your comprehensive solution for effective and accurate testing.

Imagine having the power to simulate the most demanding scenarios and ensure your BMS is ready for anything. Our BMS testbed allow you to:

- Seamlessly configure and scale your testing setup for various voltage levels.

- Access detailed cell models that support a wide range of battery chemistries.

- Utilize critical signals and protocols essential for BMS validation.

Discover how our testbed can elevate your BMS testing to new heights.

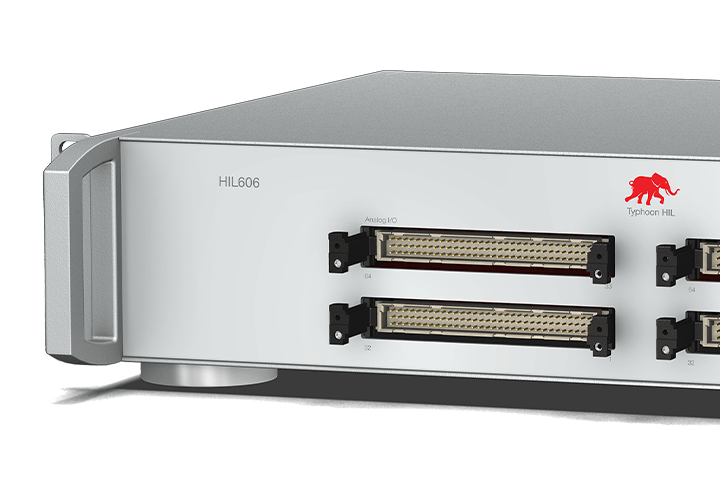

HIL606

At the core of our BMS HIL Testbed lies the HIL606, a powerful real-time simulator that acts as the brain of your entire operation. Capable of emulating models with down to 200 ns time steps, the HIL606 supports up to a quad-motor system per device, handling both analog and digital I/O, along with robust interfaces for standard automotive communication protocols. This is the precision and flexibility your BMS testing deserves.

Smart Cell Emulator

Our testbed’s Smart Cell Emulator is designed to ensure your BMS performs flawlessly. With 24 high-precision cells and 6 thermistor emulators, you have the tools to test across various voltage levels. Key features include:

- Selectable CV and CC modes for BMS and cell testing

- Output voltage range: 0 V to 8 V (with negative voltage option: -8 V to 0 V)

- Output current: ±1 A

- Dual-range current measurement with accuracy < ±5 µA ±0.05% FS

- Fault insertion capabilities: Open Circuit, Short Circuit, and Reverse Polarity

- Thermistor Emulation with 10 kΩ NTC and 10 Ω resolution

This comprehensive configuration makes the Smart Cell Emulator an indispensable part of your testing arsenal, ensuring precise and flexible validation for every aspect of your BMS.

DC Pack Voltage Emulator

No BMS testbed is complete without the ability to accurately emulate pack voltage. Our DC Pack Voltage Emulator provides up to 1000 V signals, perfectly integrated with real-time simulation, allowing for dynamic changes in response to parameter adjustments during testing. The inclusion of Isolation Resistance Emulation, up to 65.5 MΩ, ensures your BMS is tested under every conceivable condition.

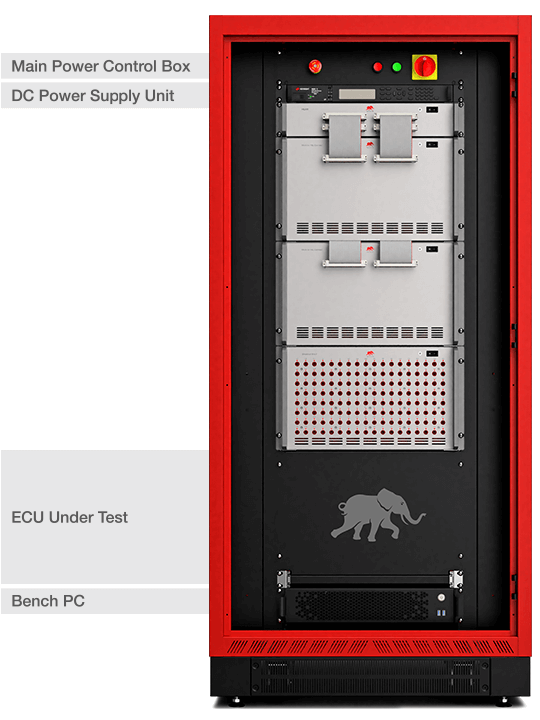

Ancillary Bench Equipment

Our BMS HIL Testbed is a complete, turnkey solution, housed in a Typhoon Red 33/37U rack and equipped with everything you need:

- Terminal Block Wiring System: Shielded and protected cabling for noise-sensitive signals.

- Main Power Control Unit (MPCU): Operates the bench power and provides safety for the operator. Equipped with automatic disconnect capability and an emergency switch.

- DC PSU: Multi-Channel DC Power Supply used for battery (KL15, KL30) simulation and board power.

- A 2U Rack Mounted Industrial PC for remote bench operation

- Dedicated BMS DUT Slot(s)

This isn’t just a testbed; it’s a comprehensive ecosystem designed to bring your BMS validation to life.