Introduction

The global demand for sustainable and energy-efficient solutions has grown dramatically in recent years. Among the critical enablers of this transition is power electronics, a field that supports a wide range of modern technologies such as electric vehicles, renewable energy systems, and smart grids. These technologies have not only captured the interest of industry and academia but are also the focus of increasing financial investments and public policy incentives aimed at accelerating their deployment.

To meet the rising expectations for reliability, performance, and adaptability, new methodologies and tools are being explored to improve how power electronics systems are developed, tested, and validated. In this context, Digital Twin technology has emerged as a powerful concept that integrates real-time simulation, bidirectional communication, and model-based engineering to provide a dynamic, accurate representation of real physical systems.

Experimental platforms based on Digital Twin concepts and implemented with Typhoon HIL real-time simulators have demonstrated significant benefits for power electronics research and experimentation. Leveraging Typhoon HIL’s Hardware-in-the-Loop (HIL) capabilities, these platforms enhance fidelity, flexibility, and speed, enabling the safe evaluation of real controllers with advanced algorithms, simulation of faulty conditions, and real-time parameter variation testing – all without the risks associated with physical prototyping of the power stage.

Challenges

A Digital Twin is a virtual representation of a real physical system. Digital Twin technology is increasingly being adopted by industries and universities to support the development of engineering projects. For this representation to be effective, synchronization and bidirectional communication between the physical and virtual components are essential.

The primary goals of Digital Twins are to understand system behavior, predict outcomes, optimize performance, and anticipate maintenance needs. Consider, for example, an electronic converter connected to the power grid. Its basic operation is governed by a controller. Over time, changes in the electrical grid or the converter’s physical components may require updates in its control algorithm. With a Digital Twin in place, such changes can be detected promptly and used to update the virtual model. The updated model can then be used to test new control strategies before they are implemented in the physical system.

Using the Typhoon HIL real-time simulator makes this process even more efficient and accurate. The HIL environment allows the physical controller to interact in real time with a high-fidelity virtual model of the power stage. This setup ensures that the control algorithm behaves as it would in a real-world scenario, significantly improving the quality and reliability of test results.

Once the virtual model is running on the HIL real-time simulator, the advantages of Digital Twin technology can be fully realized. For instance, disturbances in the power grid can be simulated, and the converter’s response can be observed. The control algorithm can then be adapted in the virtual environment, tested thoroughly, and finally deployed to the physical system.

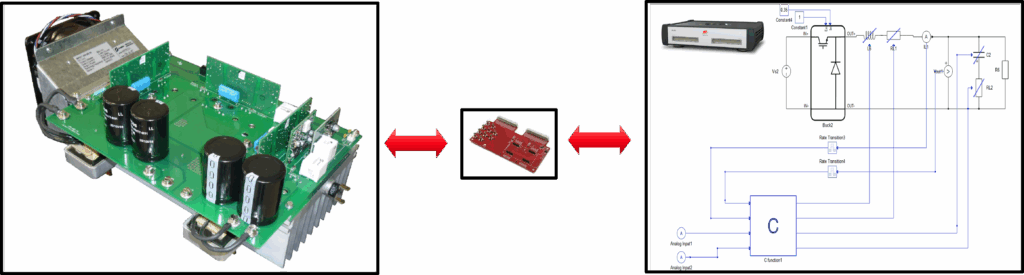

Bidirectional communication (see Fig. 1), which means sending real-time measurements from the physical system to the virtual model and control signals back to the physical converter, plays a critical role in this architecture. The Typhoon HIL platform has proven especially effective in supporting this communication with ultra-low latency and nanosecond-level simulation steps, which are essential for accurate real-time synchronization with physical controllers.

Additionally, probabilistic and statistical models can be used within the virtual environment to forecast component failures as new control strategies are tested. This predictive capability enhances system reliability and contributes to more informed, proactive decision-making.

Solution

To further enhance the realism of our real-time simulations, we integrate an external microcontroller to run the control algorithm, while the power stage remains in the virtual model. This HIL setup closely mirrors real-world operation and provides high-fidelity testing conditions. In our work with Typhoon HIL, we have modeled the system across multiple domains, as follows:

- Electrical, which includes the detailed circuitry and switching behavior.

- Thermal, which simulates heat dissipation and thermal stress in the semiconductors.

Our models cover multiple time scales, ranging from nanoseconds (semiconductor switching) to seconds (energy and power variations). The computational performance of Typhoon HIL systems is essential for executing such demanding, multiscale, and multidomain models in real time.

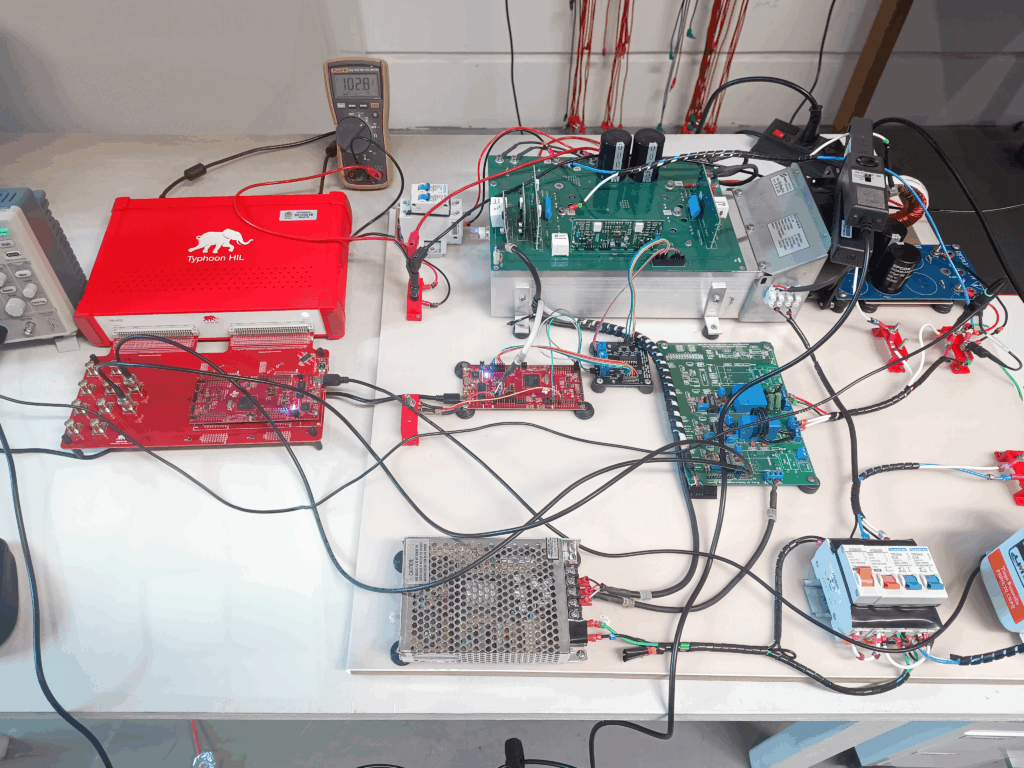

Our digital twin platforms (see a setup example in Fig. 2) are designed to be multifunctional, supporting a wide range of projects and research activities. Applications include DC-AC converters, on-grid and off-grid systems, active filters, and controlled rectifiers.

A key feature of the Digital Twin is its ability to dynamically adapt the model according to the behavior of the physical counterpart. In our work, the power stage model running in real time on the Typhoon HIL404 is updated periodically (every few minutes to several hours, depending on the application) by adjusting variable passive components. These parameters are tuned through an optimization algorithm that minimizes the quadratic error of selected converter variables, such as inductor current and capacitor voltage, between the physical converter and the HIL model. This ensures the digital twin continuously reflects the physical system, achieving higher accuracy compared to models with fixed parameters.

We’re also developing other adaptive algorithms capable of adjusting the virtual model in response to parameter variations in the physical system, such as Particle Swarm Optimization. These innovations are feasible through the advanced HIL capabilities and computational power of the Typhoon HIL platform.

Beyond technical innovations, these platforms provide significant educational value. They are actively used for hands-on training at undergraduate, master’s, and PhD levels, giving students direct exposure to cutting-edge power electronics and Digital Twin technologies. Typhoon HIL’s user-friendly interface and comprehensive simulation environment make it an ideal tool for academic training and industry collaboration.

HIL Benefits

The world is moving toward a future where electric vehicles dominate transportation, renewable energy sources supply an increasing share of our power, and smart grids optimize energy distribution. Power electronics play a crucial role in this transformation. The Digital Twin platform, supported by Typhoon HIL integrated toolchain and real-time simulators, offers a powerful toolset to accelerate this progress by providing deeper insight, greater flexibility, and enhanced precision in system design, validation, and maintenance.

The integration of Digital Twin and HIL simulation marks a significant step forward in the development of more reliable, sustainable, and intelligent power electronics systems. As battery and energy storage technologies continue to advance, power electronics will evolve in parallel, and Digital Twin technology will be essential in supporting and accelerating this evolution.

References

[1] Hge. Bai, J. Kuprat, C. Osório, C. Liu, M. Liserre, and F. Gao, “Digital Twins for Modern Power Electronics: An investigation into the enabling technologies and applications”, IEEE Electrification Magazine, vol. 12, no 3, p. 50–67, set. 2024.

[2] S. W. Butler and K. N. Parrish, “Digital Twins: The Real Opportunities [Industry Pulse]”, IEEE Power Electronics Magazine. vol. 11, no 2, p. 80–107, jun. 2024, doi: 10.1109/MPEL.2024.3395049.

[3] C. Wu, Z. Cui, Q. Xia, J. Yue, and F. Lyu, “An Overview of Digital Twin Technology for Power Electronics: State-of-the-Art and Future Trends,” in IEEE Transactions on Power Electronics, vol. 40, no. 9, pp. 13337-13362, Sept. 2025.