Wind energy is on the rise, but can your wind turbine control system weather the storm?

Modern wind turbines are no longer simple mechanical machines. They have evolved into large-scale, software-driven cyber-physical systems featuring complex controller architectures that manage everything from aerodynamic blade pitch adjustments and yaw, to grid synchronization and strict fault ride-through (FRT) compliance. As turbine capacity grows, so do the demands of homologation and regulatory testing, including fault resilience, frequency support, and reactive power control, which are all essential for safe and reliable grid integration.

In many regions, especially under The European Network Code on Requirements for Grid Connection of Generators (RfG), turbines must remain connected to the grid during voltage dips and faults, a capability known as the abovementioned FRT. This requirement helps prevent widespread outages and grid instability by ensuring turbines don’t disconnect during transient disturbances.

This growing complexity means that turbine control software must be rigorously validated. From self-diagnostics, through communication with higher level park controllers, up to intricate FRT and grid compliance behaviors, software underpins virtually every performance aspect. To effectively validate this, control systems need to be tested early, thoroughly, and under realistic, fault-inclusive operating conditions. That’s where Hardware-in-the-Loop (HIL) simulation comes in, providing engineers a safe, cost-effective, and comprehensive environment to validate turbine controls long before any physical prototype is available.

Wind: A Powerful but Unpredictable Resource

Wind is one of the four classical elements, representing movement, unpredictability, and freedom. In physics, that translates to kinetic energy, which can be harvested to generate electricity.

Wind turbine blades convert the wind’s kinetic energy into rotational energy, which drives a shaft connected to a generator, transforming mechanical power into electricity. The efficiency of this process depends on several factors, including:

- Blade length and aerodynamic design

- Blade pitch and yaw mechanisms

- Wind speed, air density, and turbulence

- Generator and inverter response

- Grid synchronization and control logic

While the wind itself is free, building and maintaining wind turbines is not. Turbines must last decades in extreme environments— sometimes at high altitudes, withstanding salt spray and heavy storms—yet also stay economically viable to install and service. Maximizing lifetime performance means using them as efficiently as possible and optimizing output across their operating life. There is a great opportunity for improving the efficiency of the output, reliability of performance, as well as longevity of wind turbines, all through improvements in the software that controls them.

The Cost of Failure

Modern turbines are growing not only in number but also in capacity. While this boosts energy output, it also increases system complexity, particularly in the electrical and control subsystems, where most failures occur. Even brief outages due to controller faults can trigger cascading losses in energy production and revenue. Moreover, wind turbines are usually delivered as complete units and their on-site repair or modification is often not feasible, as shipping repair teams and materials for remotely located ones, like in offshore wind parks, is complicated and expensive.

This makes thorough testing during the design phase essential. Modeling is valuable, but insufficient on its own. It needs to be paired with real-time testing under realistic conditions to validate performance, optimize controls, and eliminate software bugs before deployment.

Modeling a Wind Turbine for Real-Time Simulation: The Three Core Domains

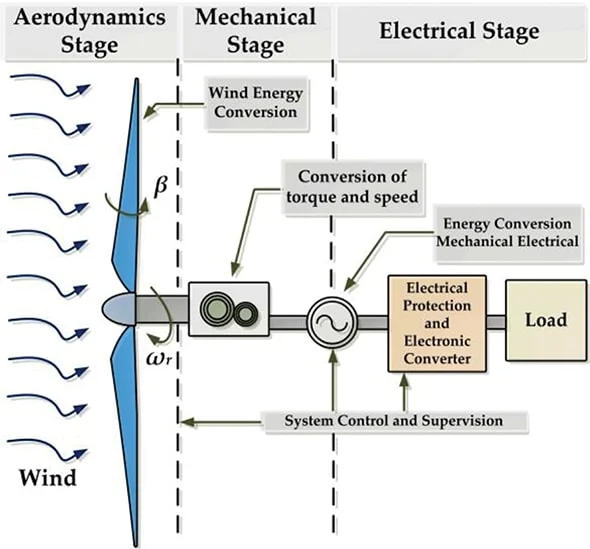

To fully simulate a wind turbine, three interconnected models (Fig. 1) must be developed:

- Aerodynamic model: Converts wind speed and direction into mechanical torque on the rotor shaft

- Mechanical model: Describes the rotational inertia, shaft dynamics, and gearbox effects

- Electrical model: Translates shaft torque into electrical output via generator and power electronics

With these models, engineers can simulate how the system responds to varying wind profiles, turbine control actions, grid events, and faults long before a single bolt is tightened.

Hardware-in-the-Loop: Bridging the Gap

HIL simulation allows engineers to test wind turbine control systems in a closed-loop environment. This means that the controller tested in HIL simulation operates exactly as it would in the real system, but instead of driving a physical turbine, it interacts with a real-time simulation of the turbine, grid, and environment.

Key benefits of HIL simulation and testing include:

- Broader test coverage for edge cases and failure modes

- Accelerated development through automated, repeatable testing

- Improved reliability and safety through early bug detection

- Cost savings by catching design issues before hardware is manufactured

- Support for CI/CD workflows with continuous integration of control code updates

With Typhoon HIL’s ultra-high fidelity, FPGA-based real-time simulation platform, developers can evaluate turbine response to gusts, grid faults, and emergency shutdowns, all without physical hardware damage or risk to personnel performing the tests.

Real-World Use Case: Reverse Wind Control

Advanced control algorithms are increasingly used to stabilize turbines in extreme wind conditions. For example, if wind speeds exceed safe limits, the system can dynamically change blade pitch or engage braking mechanisms to prevent overspeed, overheating, and damage to the wind turbine. These scenarios can be difficult and costly, sometimes even too dangerous to test in the field; however, this is straightforward to simulate with HIL.

Using Typhoon HIL solutions, engineers can:

- Implement realistic wind speed profiles

- Simulate the electric part of the turbines up to IGBT switching level with ultra-high fidelity

- Use drag and drop components from our library to model DFIG generators, multilevel inverters, and much more

- Simulate the turbine’s electrical output

- Validate the control software’s reaction in real time

- Run large automatic test suites to ensure system functionality before the first prototype or the wind turbine is built

- Automatically log results, compare versions, and detect regressions

The Betz Limit and the Business Case for Testing

No turbine can capture 100% of the wind’s energy. The Betz limit states that a maximum of 59.3% of wind power can be converted into useful mechanical energy. That means efficiency margins are tight, and every single percentage point counts. A mere 1–2% efficiency loss due to unoptimized control code can significantly reduce return on investment.

By leveraging real-time simulation and HIL testing, manufacturers and system integrators can confidently move from model to market, minimizing risk while maximizing energy yield.

Conclusion: Building Better Wind Turbines with HIL

Wind turbine control is a multidomain challenge, but the right tools make it manageable. Typhoon HIL’s platform combines advanced modeling, ultra-fast simulation, and automated test orchestration to provide developers with a comprehensive environment to test, validate, and optimize wind energy systems. Typhoon HIL enables the simulation of large full-size inverter architectures through an intuitive drag-and-drop interface, seamlessly combining them with saturable machine models (ASM, PMSM, or DFIG) on FPGA-based real-time simulators. Thanks to our advanced FPGA integration, these models can be compiled within just a few minutes and will run with full switching behavior with speeds below one microsecond.

Wind may be unpredictable. Your control system doesn’t have to be. Reach out to our team to schedule a free demo and learn how adopting our HIL solutions into your projects could help you deliver better results in less time.