HIL Compatible®

A ready-to-use HIL environment that validates complex power-electronic systems efficiently and effectively.

Digital Twins and C-HIL for Seamless Controller Integration

Modern power systems – from microgrids and industrial drives to renewable energy assets and converters, are smarter and more interconnected than ever. They rely on inverters, relays, power electronics controllers, and energy management units, all running increasingly complex embedded software. Engineers face rapid firmware updates, multi-vendor interoperability challenges, strict safety and uptime requirements, and the growing need for automated, repeatable testing. Traditional methods struggle to keep pace.

Typhoon HIL addresses this with Controller Hardware-in-the-Loop (C-HIL), a turnkey, high-fidelity environment that connects real controller hardware directly to a real-time model. Engineers can simulate any operating scenario, validate firmware safely, and verify multi-vendor interoperability — whether for grid-scale, industrial applications, or standalone power electronics devices, all without energizing a physical system.

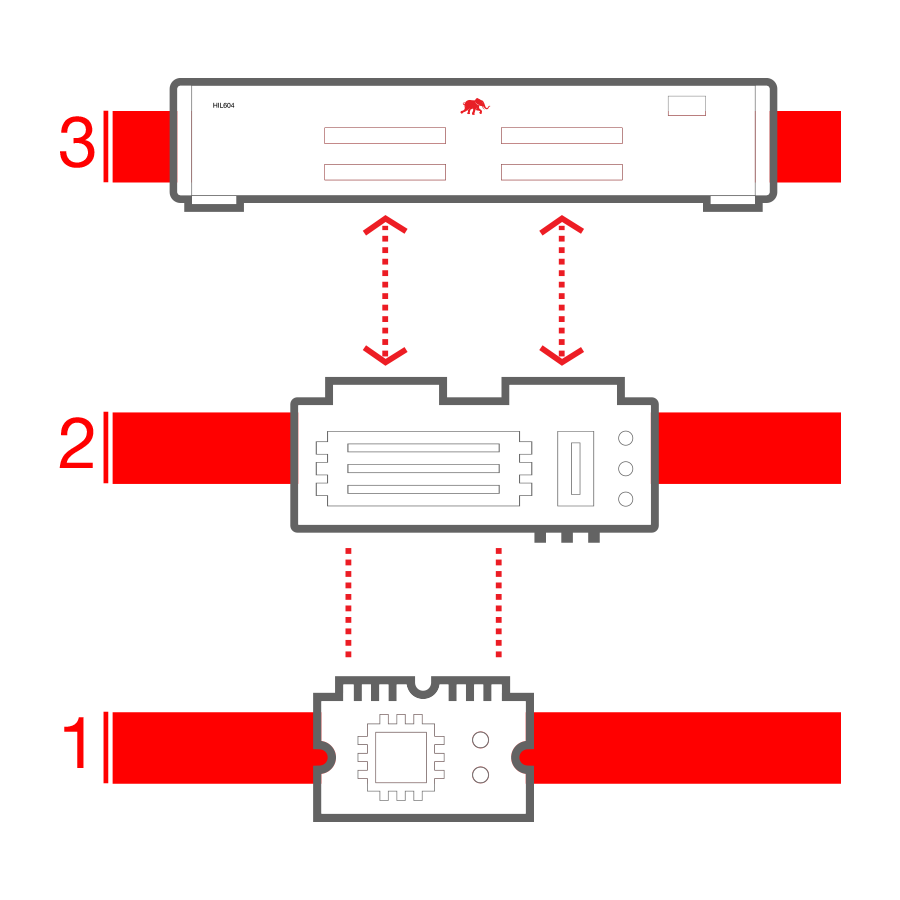

How C-HIL Works – A Complete Controller Test Environment:

- Controller – actual OEM hardware and firmware

- Interface – electrical and communication bridge between HIL and Controller

- Real-Time Model – high-fidelity digital twin running on a HIL Simulator sub-microsecond resolution

Together, these components provide a ready-to-use environment for safe, repeatable, and accurate controller validation.

From C-HIL to

HIL Compatible®

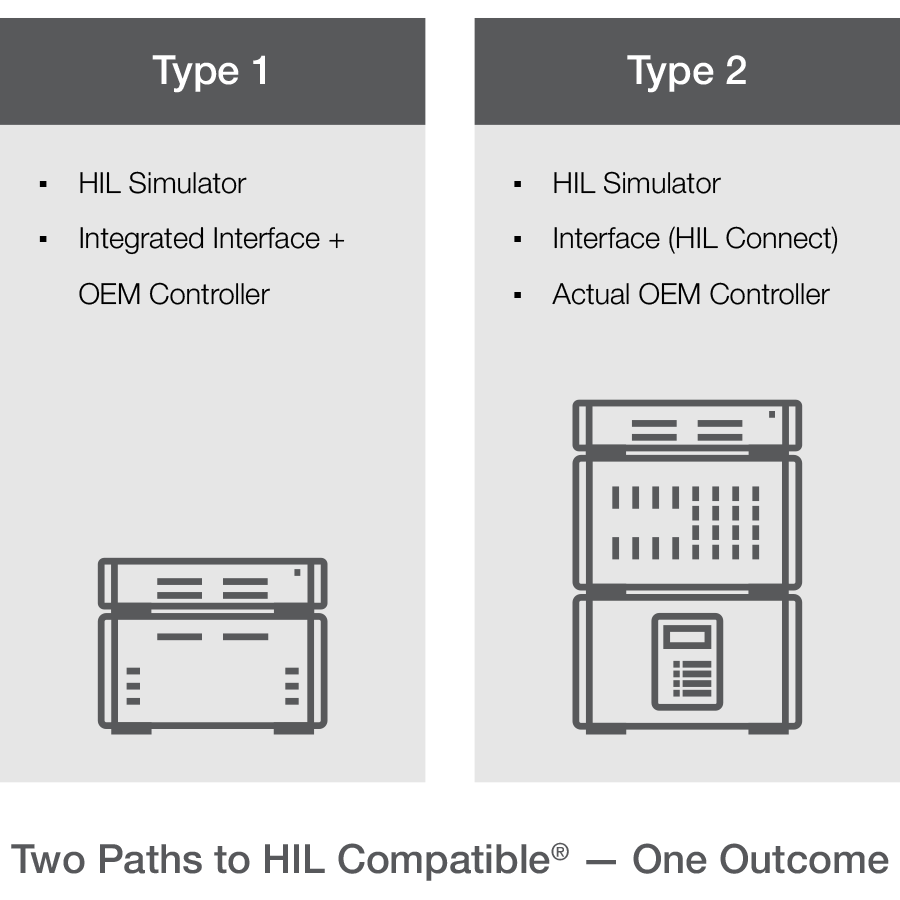

C-HIL validates an OEM controller in a controlled, high-fidelity environment. HIL Compatible® builds on this foundation, providing standardized models and interfaces that make integration across labs, integrators, and customer sites predictable and efficient. It ensures controllers operate consistently and reliably within a HIL Testbed, reducing manual configuration while maintaining the fidelity engineers expect.

Both approaches deliver the same HIL Compatible® result — efficient, repeatable, and reliable validation of controllers in a high-fidelity environment.

What Makes a Device HIL Compatible®

Hardware “Device”

The HIL Compatible device is designed as a plug-and-play solution, with an integrated OEM controller, and it provides:

- Firmware

- Configuration

- Communication mappings

- Electrical and control interfaces

Digital “Package”

Delivered via the Typhoon Marketplace or Package Manager, it provides:

- High-fidelity power electronic model

- Application examples

- Automated test examples (e.g. Python)

- Typhoon documentation and user guides

- Maintenance

- OEM configuration files

Why HIL Compatible® Matters / Benefits

HIL Compatible® transforms how OEMs and integrators collaborate, validate, and deliver energy systems, providing structured confidence and predictable results at every stage.

HIL Compatible® Devices

ABB DriveLab ACS880

Includes two ABB controller units for the ACS880 product family.

PE Gen3

Supports the HEMK PCS converter with up to two modules.

EPC Power

Supports both EPC PD500 and CAB1000 power conversion systems.

Danfoss MyDrive® HIL

IC7 Frequency Converter for HIL testing.

AIT HIL Controller

High-fidelity converter controller with plug-and-play HIL connectivity.

Contact us to learn more about HIL Compatible across major OEMs such as SEL, ComAp, Woodward, Caterpillar, DEIF, Deep Sea Electronics, ABB, Eaton, etc.