Typhoon HIL XIL API Python Guide

How to start to use ASAM XIL API for creating tests in a Python environment

Importing the XIL API .NET Assemblies

import sys

import clr

import os

import typhoon.api.hil as hil

ASSEMBLY_NAME = 'ASAM.XIL.Implementation.Testbench'

SERVER_CLASS_NAME = 'TyphoonHIL.ASAM.XIL.Server'

# Get TyphoonHIL SW version and system drive label for ASSEMBLY_ROOT path

sw_ver = hil.get_sw_version()

system_drive = os.getenv("SystemDrive")

ASSEMBLY_ROOT = r'{}\ProgramData\ASAM\XIL\Typhoon HIL Control Center {}' \

r'\XILVersion_2.1.0\C#'.format(system_drive, sw_ver)

sys.path.append(str(ASSEMBLY_ROOT))

# Add reference to the XIL API .NET assemblies

clr.AddReference(ASSEMBLY_NAME)

clr.AddReference(SERVER_CLASS_NAME)Creating a Typhoon HIL XIL API Testbench

All XIL API interfaces can be created via factory methods. A factory approach is applied in order to maximize independence of test cases from the test system. The Testbench API separates the test hardware from the test software and allows standardized access to the hardware.

import TyphoonHIL.ASAM.XIL.Server as server

testbench = server.Testbench()

print('Testbench invoked') Creating and Configuring a MA (Model Access) Port

The Testbench API covers access to the Model Access hardware. Model Access provides access to simulation model read and write parameters, capture functionality, and generated signals.

To load and apply the configuration to an MAPort instance, the LoadConfiguration and Configure methods are used.

import os

from pathlib import Path

import typhoon.api.hil as hil

from typhoon.api.schematic_editor import model

FILE_DIR_PATH = Path(__file__).parent

model_name = "test_model.tse"

model_path = os.path.join(FILE_DIR_PATH, "hil_model", model_name)

compiled_model_path = model.get_compiled_model_file(model_path)

model.load(model_path)

model.compile()

hil.load_model(compiled_model_path, vhil_device=vhil_enable)# script directory

TEST_DIR_PATH = Path(__file__).parent

MODEL_FILE_NAME = "test_model.tse"

MODEL_FILE_PATH = os.path.join(TEST_DIR_PATH, "hil_model", MODEL_FILE_NAME)

# Example of XML file

xml_content = f"""<?xml version='1.0'?>

<root>

<schematic_path>{MODEL_FILE_PATH}</schematic_path>

<vhil_device>false</vhil_device>

<debug>true</debug>

</root>"""

XML_FILE_NAME = "ModelInfo_HIL.xml"

MA_PORT_CONFIG = os.path.join(TEST_DIR_PATH, "hil_model", XML_FILE_NAME)

# Invoke Testbench

testbench = server.Testbench()

# Create MA Port

maPort = testbench.MAPortFactory.CreateMAPort('ECU-TEST MA-Port')

# Create configuration file – because we want to use a relative MODEL_FILE_PATH

with open(MA_PORT_CONFIG, 'w') as xml_f:

xml_f.write(xml_content)

# Load configuration

cfg = maPort.LoadConfiguration(str(MA_PORT_CONFIG))

# Apply to the MA Port

maPort.Configure(cfg, False)In order to maximize independence of test cases from test systems it is not sufficient to just standardize interfaces of a test system. Rather there should be a generic way to obtain corresponding instances from any vendor providing an XIL implementation. Therefore, the factory approach is applied. That means instances are obtained from methods of already existing objects.

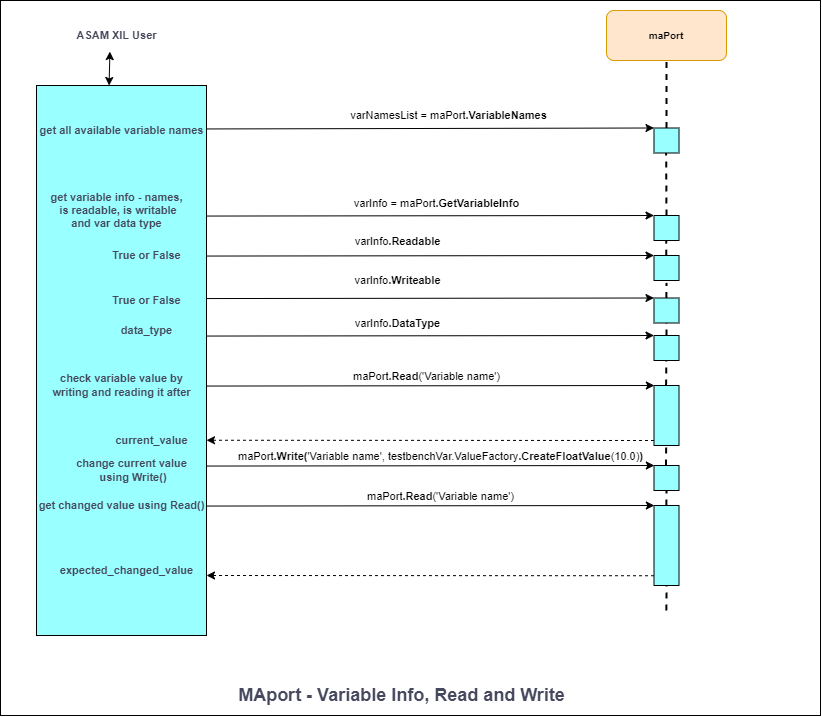

MA Port - Reading and Writing Variables

The sequence diagram in Figure 1 shows how to handle and access model variables. We assume that the XIL simulator is already initialized, and a simulation model is running. An MAPort instance is used to collect all available model variables and to check their presence in the simulation model. Before accessing a model variable, we can check if a variable's data type and if it is readable or writable through the MAPort instance. The variable can be accessed by the Read() and the Write() method of the MAPort object.

# The model is a SCADA Input connected to a Probe

setVal = 10.0

# Check if variables are readable - return True or False

canRead = maPort.IsReadable('SCADA Input1')

# Check if variables are writable - return True or False

canWrite = maPort.IsWritable('SCADA Input1')

# Get the variable data type

varDataType = maPort.GetDataType('SCADA Input1')

# Write a value to the SCADA input

maPort.Write('SCADA Input1', testbenchVar.ValueFactory.CreateFloatValue(setVal))

# Read a value from the probe

raw_probeExp = maPort.Read('Probe1')

probeExp = raw_probeExp.__raw_implementation__

print(str(probeExp.Value))MA Port - Start / Stop Simulation and Simulation States

# Start simulation – simulation can be started from MAport states:

# eDISCONNECTED or eSIMULATION_STOPPED

maPort.StartSimulation()

# The current MAport state after starting simulation is eSIMULATION_RUNNING

# Run some tests

# .

# .

# .

# Stop simulation – simulation can be stopped from MAport states:

# eSIMULATION_RUNNING

maPort.StopSimulation()

# The current MAport state after stopping simulation is eSIMULATION_STOPPED

# Disconnect from MAPort – simulation will be stopped, if not before

# Can be called from MAport states: eSIMULATION_RUNNING or eSIMULATION_STOPPED

maPort.Disconnect()

# The current MAport state after disconnecting from MAport is eDISCONNECTED

# The MAport State can be checked in the following way

currentState = maPort.State

print(“The current MAport state is: {}”.format(currentState))

maPort.Dispose()

print("MAPort DISPOSED")maPortState = {

# A connection to the port's hardware is established. Model simulation

# is not running (stopped).

0x0000: "eSIMULATION_STOPPED",

# A connection to the port's hardware is established. Model simulation

# is running.

0x0001: "eSIMULATION_RUNNING",

# A connection to the port's hardware is not established.

0x0002: "eDISCONNECTED",

}

# You can check the state of simulation by:

currentState = maPort.State

assert maPortState[currentState] == "eSIMULATION_RUNNING", "The MA Port" \

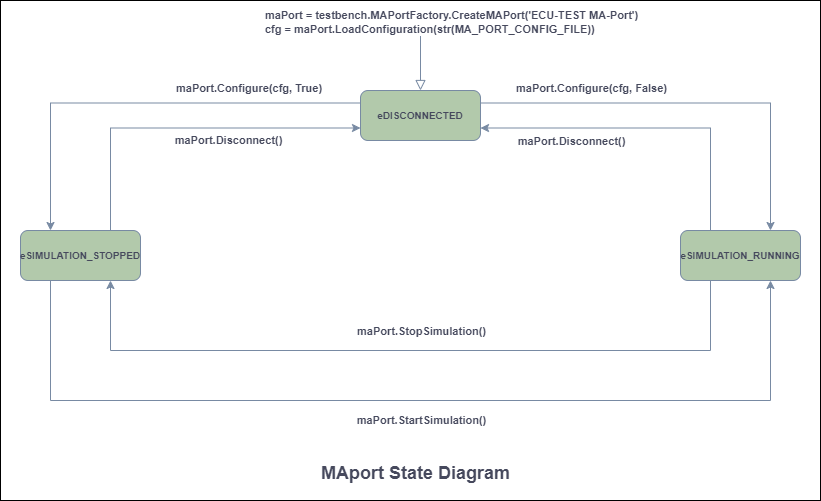

"state is not in eSIMULATION_RUNNING state."The MAport state diagram is shown in Figure 2. Here you can see which methods can be called from which states.

If you want to check which variables are in the model, you can use the VariableNames property:

# Get all variable names from the list of variable names

raw_varNamesList = maPort.VariableNames

varNamesList = raw_varNamesList.__raw_implementation__

# List of all Variable Names from the model

for variable in varNamesList:

print(str(variable))Or list of all task names using TaskNames property:

# Get all task names from the list of task names

raw_taskNames = maPort.TaskNames

taskNames = raw_taskNames.__raw_implementation__

# List of all Task Names from available list of supported tasks

for task in taskNames:

print(str(task))Capture - Create, Start, Stop Capture, and Capture States

The process of acquiring data in a continuous data stream is called CAPTURING. It guarantees that all process data can be retrieved as they occur related to the real-time service in respect to the capture service task. After completion of this process or even while it is still in progress, the data acquired can be retrieved.

The classes responsible for controlling Capture execution, as well as obtaining and displaying measured data, are accessible in the Common.Capturing package. These classes are used by MAPort instances.

The Capture class is the main class of the Capturing package. It is used to define control capture execution.

When capturing a Probe signal, signal streaming must be set. Enabling the Signal Streaming property allows acquisition and logging of the signal. An instance of the Capture class represents a capture definition. A capture is created by the port for which a capture shall be defined (MAPort in our case).

# Create and initialize a Capture object

taskName = "Capturing_Probe"

capture = maPort.CreateCapture(taskName)

# Get the current Capture State (should be "eCONFIGURED")

currentCaptureState = capture.State

# Set variables for capture

probeOutputLst = ["Probe1", "Subsystem1.Probe1"]

capture.Variables = Array[str](probeOutputLst)

# Create a CaptureResultMDFWriter object

captureResultMDFWriter =

testbenchVar.CapturingFactory.CreateCaptureResultMDFWriterByFileName(file_path)

# Capturing process – START capturing

capture.Start(captureResultMDFWriter)

# Get the current Capture State (should be "eRUNNING")

currentCaptureState = capture.State

# Capturing process – Stop must be called to explicitly stop the capture process

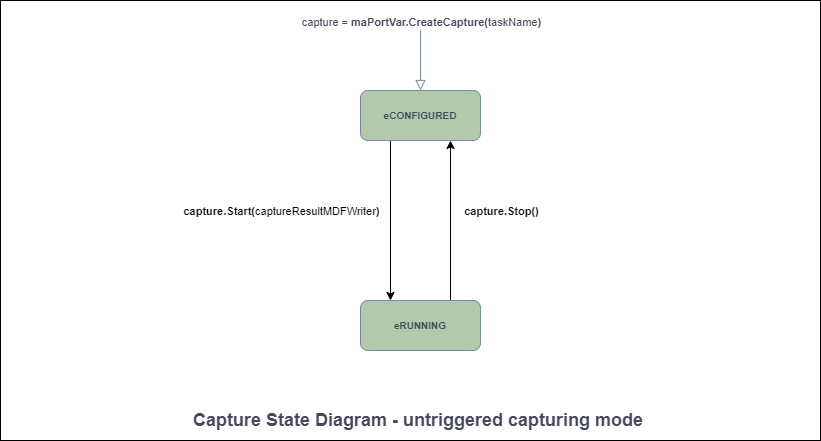

capture.Stop()Capture objects have a state representing the status of data acquisition. It can be retrieved via the Capture's state property.

file_path – path to the MDF file.

The State diagram for an untriggered capturing mode is shown in Figure 3.

Signal Segments - Creating Stimulus Signals

# Create Const segment

raw_constSegment = testbench.SignalFactory.CreateConstSegment()

constSegment = raw_constSegment.__raw_implementation__

# Set Const segment properties

constSegment.Duration = testbench.SymbolFactory.CreateConstSymbolByValue(3.4)

constSegment.Value = testbench.SymbolFactory.CreateConstSymbolByValue(5)

# Get the Segment Type (Should be “eCONST”)

segmentTyp = constSegment.Type

# Get the Duration value

print("Duration of segment is: " + str(constSegment.Duration.Value))

# Get the Segment Value

raw_const_segment_value = constSegment.Value

const_segment_value = raw_const_segment_value.__raw_implementation__

print("Value of Const segment is: " + str(const_segment_value.Value))

# Create Exponential segment

expSegment = testbenchVar.SignalFactory.CreateExpSegment()

# Set Exponential segment properties

expSegment.Duration = testbenchVar.SymbolFactory.CreateConstSymbolByValue(5)

expSegment.Start = testbenchVar.SymbolFactory.CreateConstSymbolByValue(1)

expSegment.Stop = testbenchVar.SymbolFactory.CreateConstSymbolByValue(4)

expSegment.Tau = testbenchVar.SymbolFactory.CreateConstSymbolByValue(0.63)

# Get the Segment Type (Should be “eEXP”)

segmentTyp = expSegment.Type

# Get the Duration value

print("Duration of Exp segment is: " + str(exp_segment.Duration.Value))

# Get the Start value

raw_exp_segment_start = expSegment.Start

exp_segment_start = raw_exp_segment_start.__raw_implementation__

print("Start value of Exp segment is: " + str(exp_segment_start.Value)

# Get the Stop value

raw_exp_segment_stop = expSegment.Stop

exp_segment_stop = raw_exp_segment_stop.__raw_implementation__

print("Stop after: " + str(exp_segment_stop.Value))

# Get the Tau value

raw_exp_segment_tau = expSegment.Tau

exp_segment_tau = raw_exp_segment_tau.__raw_implementation__

print("Value of Tau is: " + str(exp_segment_tau.Value))

# Create Ramp segment

rampSegment = testbenchVar.SignalFactory.CreateRampSegment()

# Set Ramp segment properties

rampSegment.Duration = testbenchVar.SymbolFactory.CreateConstSymbolByValue(5)

rampSegment.Start = testbenchVar.SymbolFactory.CreateConstSymbolByValue(1)

rampSegment.Stop = testbenchVar.SymbolFactory.CreateConstSymbolByValue(6)

# Get the Segment Type (Should be “eRAMP”)

segmentTyp = rampSegment.Type

# Get the Duration value

print("Duration of Ramp segment is: " + str(ramp_segment.Duration.Value))

# Get the Start value

raw_ramp_segment_start = rampSegment.Start

ramp_segment_start = raw_ramp_segment_start.__raw_implementation__

print("Start value of Ramp segment is: " + str(ramp_segment_start.Value))

# Get the Stop value

raw_ramp_segment_stop = rampSegment.Stop

ramp_segment_stop = raw_ramp_segment_stop.__raw_implementation__

print("Value of Ramp segment is: " + str(ramp_segment_stop.Value))

# Create RampSlope segment

rampSlopeSegment = testbenchVar.SignalFactory.CreateRampSlopeSegment()

# Set RampSlope segment properties

rampSlopeSegment.Duration = testbenchVar.SymbolFactory.CreateConstSymbolByValue(5)

rampSlopeSegment.Offset = testbenchVar.SymbolFactory.CreateConstSymbolByValue(1)

rampSlopeSegment.Slope = testbenchVar.SymbolFactory.CreateConstSymbolByValue(5)

# Get the Segment Type (Should be “eRAMPSLOPE”)

segmentTyp = rampSlopeSegment.Type

# Get the Duration value

print("Duration of RampSlope segment is: " + str(rampSlopeSegment.Duration.Value))

# Get the Offset value

raw_rampSlopeSegment_offset = rampSlopeSegment.Offset

rampSlopeSegment_offset = raw_rampSlopeSegment_offset.__raw_implementation__

print("Offset value of RampSlope segment is: " + str(rampSlopeSegment_offset.Value))

# Get the Slope value

raw_rampSlopeSegment_slope = rampSlopeSegment.Slope

rampSlopeSegment_slope = raw_rampSlopeSegment_slope.__raw_implementation__

print("Value of RampSlope segment is: " + str(rampSlopeSegment_slope.Value))

# Create Sine segment

sineSegment = testbenchVar.SignalFactory.CreateSineSegment()

# Set Sine segment properties

sineSegment.Amplitude = testbenchVar.SymbolFactory.CreateConstSymbolByValue(10)

sineSegment.Duration = testbenchVar.SymbolFactory.CreateConstSymbolByValue(5)

sineSegment.Offset = testbenchVar.SymbolFactory.CreateConstSymbolByValue(1)

sineSegment.Period = testbenchVar.SymbolFactory.CreateConstSymbolByValue(0.25)

sineSegment.Phase = testbenchVar.SymbolFactory.CreateConstSymbolByValue(3)

# Get the Segment Type (Should be “eSINE”)

segmentTyp = sineSegment.Type

# Get the Amplitude value

raw_sineSegment_amplitude = sineSegment.Amplitude

sineSegment_amplitude = raw_sineSegment_amplitude.__raw_implementation__

print("Amplitude of Sine segment is: " + str(sineSegment_amplitude.Value))

# Get the Duration value

print("Duration of Sine segment is: " + str(sineSegment.Duration.Value))

# Get the Offset value

raw_sineSegment_offset = sineSegment.Offset

sineSegment_offset = raw_sineSegment_offset.__raw_implementation__

print("Offset value of Sine segment is: " + str(sineSegment_offset.Value))

# Get the Period value

raw_sineSegment_period = sineSegment.Period

sineSegment_period = raw_sineSegment_period.__raw_implementation__

print("Value of Sine segment is: " + str(sineSegment_period.Value))

# Get the Phase value

raw_sineSegment_phase = sineSegment.Phase

sineSegment_phase = raw_sineSegment_phase.__raw_implementation__

print("Value of Sine segment is: " + str(sineSegment_phase.Value))

# Create Noise segment

noiseSegment = testbenchVar.SignalFactory.CreateNoiseSegment()

# Set Noise segment properties

noiseSegment.Duration = testbenchVar.SymbolFactory.CreateConstSymbolByValue(10)

noiseSegment.Mean = testbenchVar.SymbolFactory.CreateConstSymbolByValue(5)

noiseSegment.Sigma = testbenchVar.SymbolFactory.CreateConstSymbolByValue(1)

noiseSegment.Seed = testbenchVar.SymbolFactory.CreateConstSymbolByValue(4)

# Get the Segment Type (Should be “eNOISE”)

segmentTyp = noiseSegment.Type

# Get the Duration value

print("Duration of segment is: " + str(noiseSegment.Duration.Value))

# Get the Mean value

raw_noiseSegment_mean = noiseSegment.Mean

noiseSegment_mean = raw_noiseSegment_mean.__raw_implementation__

print("Mean of Noise segment is: " + str(noiseSegment_mean.Value))

# Get the Seed value

raw_noiseSegment_seed = noiseSegment.Seed

noiseSegment_seed = raw_noiseSegment_seed.__raw_implementation__

print("Seed of Noise segment is: " + str(noiseSegment_seed.Value))

# Get the Sigma value

raw_noiseSegment_sigma = noiseSegment.Sigma

noiseSegment_sigma = raw_noiseSegment_sigma.__raw_implementation__

print("Sigma of Noise segment is: " + str(noiseSegment_sigma.Value))

# Create Saw segment

sawSegment = testbenchVar.SignalFactory.CreateSawSegment()

# Set Saw segment properties

sawSegment.Duration = testbenchVar.SymbolFactory.CreateConstSymbolByValue(10)

sawSegment.Offset = testbenchVar.SymbolFactory.CreateConstSymbolByValue(5)

sawSegment.Period = testbenchVar.SymbolFactory.CreateConstSymbolByValue(1)

sawSegment.Amplitude = testbenchVar.SymbolFactory.CreateConstSymbolByValue(4)

sawSegment.Phase = testbenchVar.SymbolFactory.CreateConstSymbolByValue(0)

sawSegment.DutyCycle = testbenchVar.SymbolFactory.CreateConstSymbolByValue(1)

# Get the Segment Type (Should be “eNOISE”)

segmentTyp = sawSegment.Type

# Get the Duration value

print("Duration of segment is: " + str(sawSegment.Duration.Value))

# Get the Offset value

raw_sawSegment_offset = sawSegment.Offset

sawSegment_offset = raw_sawSegment_offset.__raw_implementation__

print("Offset of Saw segment is: " + str(sawSegment_offset.Value))

# Get the Period value

raw_sawSegment_period = sawSegment.Period

sawSegment_period = raw_sawSegment_period.__raw_implementation__

print("Period of Saw segment is: " + str(sawSegment_period.Value))

# Get the Amplitude value

raw_sawSegment_amplitude = sawSegment.Amplitude

sawSegment_amplitude = raw_sawSegment_amplitude.__raw_implementation__

print("Amplitude of Saw segment is: " + str(sawSegment_amplitude.Value))

# Get the Phase value

raw_sawSegment_phase = sawSegment.Phase

sawSegment_phase = raw_sawSegment_phase.__raw_implementation__

print("Phase of Saw segment is: " + str(sawSegment_phase.Value))

# Get the DutyCycle value

raw_sawSegment_dutycycle = sawSegment.DutyCycle

sawSegment_dutycycle = raw_sawSegment_dutycycle.__raw_implementation__

print("DutyCycle of Saw segment is: " + str(sawSegment_dutycycle.Value))

# Create Pulse segment

pulseSegment = testbenchVar.SignalFactory.CreatePulseSegment()

# Set Pulse segment properties

pulseSegment.Duration = testbenchVar.SymbolFactory.CreateConstSymbolByValue(10)

pulseSegment.Offset = testbenchVar.SymbolFactory.CreateConstSymbolByValue(5)

pulseSegment.Period = testbenchVar.SymbolFactory.CreateConstSymbolByValue(1)

pulseSegment.Amplitude = testbenchVar.SymbolFactory.CreateConstSymbolByValue(4)

pulseSegment.Phase = testbenchVar.SymbolFactory.CreateConstSymbolByValue(0)

pulseSegment.DutyCycle = testbenchVar.SymbolFactory.CreateConstSymbolByValue(1)

# Get the Segment Type (Should be “eNOISE”)

segmentTyp = pulseSegment.Type

# Get the Offset value

raw_pulseSegment_offset = pulseSegment.Offset

pulseSegment_offset = raw_pulseSegment_offset.__raw_implementation__

print("Offset of Pulse segment is: " + str(pulseSegment_offset.Value))

# Get the Period value

raw_pulseSegment_period = pulseSegment.Period

pulseSegment_period = raw_pulseSegment_period.__raw_implementation__

print("Period of Pulse segment is: " + str(pulseSegment_period.Value))

# Get the Phase value

raw_pulseSegment_phase = pulseSegment.Phase

pulseSegment_phase = raw_pulseSegment_phase.__raw_implementation__

print("Phase of Pulse segment is: " + str(pulseSegment_phase.Value))

# Get the DutyCycle value

raw_pulseSegment_dutycycle = pulseSegment.DutyCycle

pulseSegment_dutycycle = raw_pulseSegment_dutycycle.__raw_implementation__

print("DutyCycle of Pulse segment is: " + str(pulseSegment_dutycycle.Value))

# Operation signal segment

from ASAM.XIL.Interfaces.Testbench.Common.Signal.Enum import OperationTypes

# Create Operation segment

operationSegment = testbench_var.SignalFactory.CreateOperationSegment()

# enum OperationTypes

# eADD = 0,

# eMULT = 1

operationSegment.Operation = OperationTypes(0)

print("The operation is : " + str(operationSegment.Operation))

# ******************* Set the values for Left segment ****************************************************

# Create Left segment

operationSegment.LeftSegment = testbench_var.SignalFactory.CreateRampSegment()

raw_operationSegment_left = operationSegment.LeftSegment

operationSegment_left = raw_operationSegment_left.__raw_implementation__

print("The type of LeftSegment is: " + str(type(operationSegment_left)))

# Set the value for Duration of Left segment (Ramp) and check it

operationSegment_left.Duration = (testbench_var.SymbolFactory.CreateConstSymbolByValue(5.0))

print("Duration of segment is: " + str(operationSegment_left.Duration.Value))

# Set the Start value of Left segment (Ramp) and check it

operationSegment_left.Start = testbench_var.SymbolFactory.CreateConstSymbolByValue(0.0)

raw_operationSegment_left_start = operationSegment_left.Start

operationSegment_left_start = raw_operationSegment_left_start.__raw_implementation__

print("Start value of Ramp segment is: " + str(operationSegment_left_start.Value))

# Set the Stop value of Left segment (Ramp) and check it

operationSegment_left.Stop = testbench_var.SymbolFactory.CreateConstSymbolByValue(5.0)

raw_operationSegment_left_stop = operationSegment_left.Stop

perationSegment_left_stop = raw_operationSegment_left_stop.__raw_implementation__

print("Value of Ramp segment is: " + str(operationSegment_left_stop.Value))

# Get the Segment Type and check it

segment_typ = operationSegment_left.Type

print("Type of segment is: " + str(segment_typ))

# ******************* Set the values for Right segment ****************************************************

# Create Left segment

operationSegment.RightSegment = testbench_var.SignalFactory.CreateConstSegment()

raw_operationSegment_right = operationSegment.RightSegment

operationSegment_right = raw_operationSegment_right.__raw_implementation__

print("The type of RightSegment is: " + str(type(operationSegment_right)))

# Set the value for Duration of Right segment (Const)

operationSegment_right.Duration = (testbench_var.SymbolFactory.CreateConstSymbolByValue(5.0))

raw_operationSegment_right_duration = operationSegment_right.Duration

operationSegment_right_duration = (raw_operationSegment_right_duration.__raw_implementation__)

print("Duration of segment is: " + str(operationSegment_right_duration.Value))

# Set the Value of Const segment

operationSegment_right.Value = testbench_var.SymbolFactory.CreateConstSymbolByValue(5.0)

raw_operationSegment_right_value = operationSegment_right.Value

operationSegment_right_value = (raw_operationSegment_right_value.__raw_implementation__)

print("Value of Const segment is: " + str(operationSegment_right_value.Value))

# Get the Segment Type

segment_typ = operationSegment_right.Type

print("Type of segment is: " + str(segment_typ))If you want to create a SignalValue signal segment then you need to create it manually in Typhoon HIL, with 3rd party tools, or by loading a segment from a .STI file.

The signal description file is used to serialize objects of type SignalDescriptionSet, and furthermore to serialize objects of type SignalGenerator. The signal description file is an XML file with the file extension STI.

Generating Stimulus Signals

In order to use signals for stimulation, a signal generator is used. A signal generator relates signals to model variables and controls the signal generation process.

channels_list = [(["SampleSignal1"]), (["SampleSignal2"]), (["SampleSignal3"])]

# Read signals from STI file

stiReader = testbench.SignalGeneratorFactory.CreateSignalGeneratorSTIReaderByFileName(STI_FILE_PATH)

# Create Signal Generator

signalGenerator = maPort.CreateSignalGenerator()

# Load signal from STI file

signalGenerator.Load(stiReader)

# Check the state of SigGen – should be eIN_CONFIGURATION

sigGenState = signalGenerator.State

# Assign a signal (SampleSignal1) to the model variable

modelVarName1 = "SCADA Input1"

assignmentsDict = Dictionary[str, str]()

assignmentsDict[channels_list[0]] = modelVarName1

# Sets the mapping of signal descriptions to model variables

signalGenerator.Assignments = assignmentsDict

# Load signal to the Typhoon HIL device - switch to the state eREADY

signalGenerator.LoadToTarget()

# Start Signal Generator - switch to the state eRUNNING

signalGenerator.Start()

# Make some measurements - Capture the signal

# .

# .

# .

# Pause signal generator before signal end - switch to the state ePAUSED

signalGenerator.Pause()

# Make some changes – for example change the signal

# .

# .

# .

# Start Signal Generator - switch to the state eRUNNING

signalGenerator.Start()

# Stop the Signal Generator – switch to the state eSTOPPED

signalGenerator.Stop()A SignalGenerator defines stimuli and manages their execution. For the definition of a stimulus, a SignalDescriptionSet is referenced by the SignalGenerator. The signals from the SignalDescriptionSet are assigned with model variables in the "Assignments" collection. To manage stimuli, functionality is provided for downloading a stimulus to the target system, for starting, stopping, and pausing it and for observing its current state.

<?xml version="1.0" encoding="utf-8"?>

<SignalDescriptionFile xmlns="http://www.asam.net/XIL/Signal/2.2.0" xmlns:xsi="http://www.w3.org/2001/XMLSchema-instance" xsi:schemaLocation="http://www.asam.net/XIL/Signal/2.2.0 ../SignalDescriptionFormat.xsd">

<!-- Signal generator file demonstrating the assignment of signal descriptions to target system variables -->

<SignalDescriptionSet>

<SignalDescription name="SampleSignal1" id="ID_SIGNAL_SampleSignal1">

<SegmentSignalDescription>

<ConstSegment>

<Duration xsi:type="ConstSymbol">

<Value>1.0</Value>

</Duration>

<Value xsi:type="ConstSymbol">

<Value>1</Value>

</Value>

</ConstSegment>

<RampSegment>

<Duration xsi:type="ConstSymbol">

<Value>3.4</Value>

</Duration>

<Start xsi:type="ConstSymbol">

<Value>1</Value>

</Start>

<Stop xsi:type="ConstSymbol">

<Value>10</Value>

</Stop>

</RampSegment>

<RampSlopeSegment>

<Duration xsi:type="ConstSymbol">

<Value>8</Value>

</Duration>

<Slope xsi:type="ConstSymbol">

<Value>1</Value>

</Slope>

<Offset xsi:type="ConstSymbol">

<Value>7.5</Value>

</Offset>

</RampSlopeSegment>

<ExpSegment>

<Duration xsi:type="ConstSymbol">

<Value>4</Value>

</Duration>

<Start xsi:type="ConstSymbol">

<Value>1</Value>

</Start>

<Stop xsi:type="ConstSymbol">

<Value>5</Value>

</Stop>

<Tau xsi:type="ConstSymbol">

<Value>0.5</Value>

</Tau>

</ExpSegment>

<SineSegment>

<Duration xsi:type="ConstSymbol">

<Value>4</Value>

</Duration>

<Amplitude xsi:type="ConstSymbol">

<Value>3</Value>

</Amplitude>

<Period xsi:type="ConstSymbol">

<Value>2</Value>

</Period>

<Phase xsi:type="ConstSymbol">

<Value>1</Value>

</Phase>

<Offset xsi:type="ConstSymbol">

<Value>-1</Value>

</Offset>

</SineSegment>

<NoiseSegment>

<Duration xsi:type="ConstSymbol">

<Value>1.0</Value>

</Duration>

<Mean xsi:type="ConstSymbol">

<Value>2.0</Value>

</Mean>

<Seed xsi:type="ConstSymbol">

<Value>3.5</Value>

</Seed>

<Sigma xsi:type="ConstSymbol">

<Value>0.5</Value>

</Sigma>

</NoiseSegment>

<SawSegment>

<Amplitude xsi:type="ConstSymbol">

<Value>2.0</Value>

</Amplitude>

<Duration xsi:type="ConstSymbol">

<Value>5.0</Value>

</Duration>

<DutyCycle xsi:type="ConstSymbol">

<Value>0.5</Value>

</DutyCycle>

<Offset xsi:type="ConstSymbol">

<Value>-2.0</Value>

</Offset>

<Period xsi:type="ConstSymbol">

<Value>1.0</Value>

</Period>

<Phase xsi:type="ConstSymbol">

<Value>0.25</Value>

</Phase>

</SawSegment>

<PulseSegment>

<Amplitude xsi:type="ConstSymbol">

<Value>1.0</Value>

</Amplitude>

<Duration xsi:type="ConstSymbol">

<Value>5.0</Value>

</Duration>

<DutyCycle xsi:type="ConstSymbol">

<Value>0.9</Value>

</DutyCycle>

<Offset xsi:type="ConstSymbol">

<Value>-2.0</Value>

</Offset>

<Period xsi:type="ConstSymbol">

<Value>1.0</Value>

</Period>

<Phase xsi:type="ConstSymbol">

<Value>0.25</Value>

</Phase>

</PulseSegment>

</SegmentSignalDescription>

</SignalDescription>

</SignalDescriptionSet>

</SignalDescriptionFile>The format of the STI file is defined via an XML schema definition file. All signals and segments are serialized in their corresponding XML tags. Due to performance issues the numerical values of the SignalValueSegment are serialized in a separate MATLAB file (.mat) and not in the XML file.

MAPort - Creating and Using ConditionWatcher

The ConditionWatcher fires when the condition specified by the property Condition becomes true after its activation. The condition syntax is validated when the property Condition is set. As soon as the specified condition becomes true, the ConditionWatcher fires. The ConditionWatcher’s condition may contain signals or parameters of the simulation model. To shorten the condition expression, aliases for the simulation variables are used which are mapped to model paths. The mapping can be defined via the property ‘Defines’.

In order to prevent the program of blocking endlessly, the property TimeOut of the ConditionWatcher should be set. This ensures, that the ConditionWatcher stops evaluating its condition and fires its event as soon as the duration given by TimeOut is elapsed. If a timeout value of zero is given, the ConditionWatcher fires its event immediately and the specified condition is ignored.

The model shown in Figure 4 together with the code below shows an example of the usage of Condition Watcher. The model from this example consists of a Ramp (signal generator) and Probe1 for monitoring the value of the signal.

from TyphoonHIL.ASAM.XIL import Server

from TyphoonHIL.ASAM.XIL.Server.MAPort import SampleBreakPoint

from ASAM.XIL.Interfaces.Testbench.MAPort.Enum import BreakpointAction

XML_FILE_NAME = "ModelInfo_HIL.xml"

MA_PORT_CONFIG = os.path.join(TEST_DIR_PATH, "hil_model", XML_FILE_NAME)

# Invoke Testbench

testbench = server.Testbench()

# Create MA Port

ma_port = testbench.MAPortFactory.CreateMAPort('ECU-TEST MA-Port')

# Create configuration file – because we want to use a relative MODEL_FILE_PATH

with open(MA_PORT_CONFIG, 'w') as xml_f:

xml_f.write(xml_content)

# Load configuration

cfg = maPort.LoadConfiguration(str(MA_PORT_CONFIG))

# Apply to the MA Port

maPort.Configure(cfg, False)

# Create WatcherFactory

cond_watch = testbench.WatcherFactory

# Create a C# Dictionary <string, string> object

definesDict = Dictionary[str, str]()

# Define the condition and dictionary entries

condition = "value > 2"

definesDict["value"] = "Probe1"

# Create the instance of Condition Watcher - call the CreateConditionWatcher method

cw_instance = cond_watch.CreateConditionWatcher(condition, definesDict)

# Set the TimeOut of Condition Watcher

cw_instance.TimeOut = 5

# Start the simulation

maPort.StartSimulation()

# Create the instance of MAPortBreakpoint

ma_port_break_point = SampleBreakPoint(cw_instance, BreakpointAction.eNONE)

# Set the Breakpoint property

maPort.Breakpoint = ma_port_break_point

# Get TimeOut attribute

timeout = cw_instance.TimeOut

# Invoke WaitForBreakpoint function

maPort.WaitForBreakpoint(timeout)