Overview

Introduction to HIL Paralleling

The HIL paralleling feature provides the ability to connect multiple HIL devices into a single functional unit. This means single device capability can be extended by means of processing power and IO capacity.

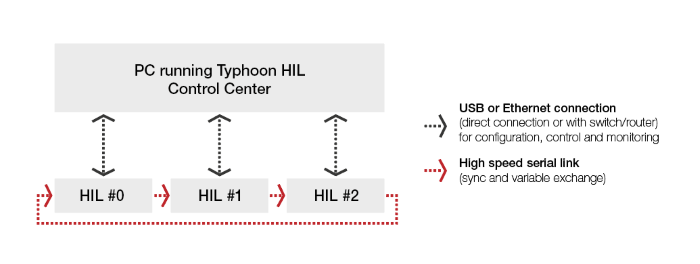

In paralleling operation, multiple devices (of the same type) are connected in a multi-HIL configuration using high speed serial link ports on the back plate. The Schematic Editor model under test must be divided into a number of sub-circuits where each sub-circuit is simulated on one parallel HIL unit (in a similar concept to multi-SPC models). A link between devices is used for synchronization and variable exchange between sub-circuits. Each device has its own network ID number which you can specify on the device.

All devices in a multi-HIL configuration should be connected to a single computer using either direct USB or Ethernet connection. The multi-HIL configuration is controlled by a single instance of the Typhoon HIL Control Panel application or its API. The multi-HIL user experience is similar to single device operation. This means:

- single button simulation start/stop

- controls for all elements (sources, contractors, machines, switching blocks, etc.) are centralized

- signals from all sub-circuits are available in the Scope and Capture widget/functions

However, it is important to note that there are some differences:

- the sub-circuit digital and analog interface is limited to the single device it is mapped to (e.g., the converter can be fired only by digital inputs of the HIL it is running on)

- the data exchange latency between devices depends on the number of units and the device order, and it is on the level of several simulation steps